The Ultimate M4 Upper Guide

Written By

Michael Crites

Licensed Concealed Carry Holder

Reviewed by

Editorial Team

Learn About The Editorial Team

Share:

Products are selected by our editors. We may earn a commission on purchases from a link. How we select gear.

Updated

Sep 2023

Selecting the perfect M4 style upper receiver can be confusing, especially when it comes down to all the assorted flavors that are floating around out there.

However, we have done the homework to answer those questions and guide you to the best options in what to look for in a good M4 upper.

In This Article

M4 Upper Reviews

As complete AR uppers are available in a widely varied array of barrel lengths, twist rates, barrel contours, handguards, and gas systems– all metrics that are subject to rapid change by the manufacturers– we are going to touch on stripped uppers which are bare of all the above and provide a great starting point for any build or upgrade.

Keep in mind, though, that if a company sells a stripped upper, odds are they also sell a variety of complete uppers in some of the most commonly-requested styles.

Also, although some of these aren’t described as being “M4” uppers, if they meet all the benchmarks of being such (M4 feed ramps, rear-charging, flat-top construction with a Pic rail, allowance for a forward assist, “mil-spec” takedown lugs, etc.) we have it on our list.

In other words, if it looks like an M4 upper, walks like an M4 upper, and quacks like an M4 upper, we’re good with it being an M4 upper.

1. Anderson

Kentucky’s Anderson Manufacturing is often criticized as being the “poverty pony” by some but there is nothing wrong with their Mil-Spec AM-15 T-marked upper.

It is forged 7075-T6 aluminum, runs M4 feed ramps, works with all standard AR-15 calibers except big bores, has a top Pic rail with T-markings, and carries a Type 3 hard anodized coating.

If you are good with applying your own coating or finish, Anderson sells these “in the white” for as low as $65.

2. Aero Precision

Aero Precision has sold tens of thousands of AR uppers and lowers over the years and for good reason: they just plain out work.

Their sleekly-cut M4E1 series upper is practically the standard for the industry. Forged from 7075-T6 aluminum, they accept all standard mil-spec AR15 parts, include M4 feed ramps, and are precision machined from an enhanced forging to look more finished than a lot of the competition.

Plus, they use a one-piece mounting system for the handguard that is integrated into the upper receiver forging itself.

3. ATI

American Tactical Inc is based in South Carolina and, while they are best known for their imports from overseas, they also market ARs and components.

ATI’s stripped M4 upper receiver is forged from 7075-T6 aluminum and features M4-type feed cuts inside for reliable feeding along with T-marks on the Picatinny rail. Compatible with standard mil-spec AR lower receivers and components, these are a great deal on a high-quality receiver.

4. Ballistic Advantage

Founded in 2008 and based out of Ocoee, Florida, Ballistic Advantage these days is a majority-owned subsidiary of Aero Precision, one of the best names in the AR game.

Their Enhanced Upper has everything you look want: forged 7075-T6 aluminum, flat-topped with T-marked Pic rail, M4 feed ramps, .250 takedown pin holes, and a smoothed billet look without the billet price.

5. Bear Creek

While North Carolina-based Bear Creek Arsenal sells a line of fine BC-15 rear-charging billet uppers, which fall into the category of M4 uppers, they also offer something a little bit different: side-charging AR uppers oriented to either the left or right.

Bear Creek’s Gen 2 side-chargers naturally take a slightly different BCG that the company sells alongside the upper, and they advertise it will work with any mil-spec .223 Rem, 5.56 NATO, .300 Blackout, or .350 Legend barrel.

6. BCM

Bravo Company MFG makes one of the best M4 uppers on the market. Besides all the stuff you expect us to expect (e.g., M4 feed ramps, Mil-Std 1913 top rail with laser-etched T-markings, fully-assembled forward assist and ejection port over) BCM pays special attention to being correct to Mil-Spec down to the Mil-A-8625F standard on the anodizing and dry film lube on the interior bore.

Additionally, their uppers are gently undersized on the inside diameter where the barrel extension inserts for a tighter fit to the barrel and a more accurate rifle.

7. BRN-15

Brownells has its own line of in-house AR/M16 rifles, pistols, and components dubbed the BRN-16 for retro builds and BRN-15 for more modern tastes.

The company’s BRN-15 M4 stripped upper is legit, has all the features you need (7075-T6, top Pic rail, M4 feed ramps, .250 pin holes, mil-spec dimensions), and usually only runs about $70.

8. Daniel Defense

By far, Georgia’s Daniel Defense sells way more completed upper receiver group (URG) assemblies than stripped receivers, but they DO sell them.

The catch is that they are rare in the wild and usually sell out within hours of being posted at dealers like Midway and Brownells or on Daniel’s own site so you have to keep your eyes peeled.

Listed as a 7075-T6 A4 receiver, they have M4 feed ramps, a T-marked top Pic rail on a flat top, and a polymer ejection port cover.

If you are serious about a serious AR build, you can do a lot worse than a DD upper as part of your foundation, especially when you consider they only cost about $60-70 more than an Anderson or PSA– if you can find them.

8. Diamondback

Florida’s Diamondback Firearms is a sleeper when it comes to ARs and AR components. One of the pleasant things about them is they make good stuff and haven’t been bitten by the bug of raising prices to correspond with the increase in demand. Take their stripped “A3” flat-top uppers for instance.

They run about $50 ish, making them one of the best uppers for those who are budget-minded and have M4 feed ramps to promote reliable feeding.

As a bonus, they not only offer them in the standard black hard coat anodized finish, but also in Cerakote flat dark earth, midnight bronze, olive drab green, and tactical grey for about the same price point.

8. Palmetto State

South Carolina’s Palmetto State Armory sells a ton of uppers from other folks, but they also market their own line of unmarked stripped M4 uppers as well.

Made of forged 7075-T6 aluminum with an A3 flat top that has a Pic rail (but no T-marks) it is mil-spec and hard coat anodized for durability.

As would be expected, it has M4 feed ramp cuts.

How are upper receivers different?

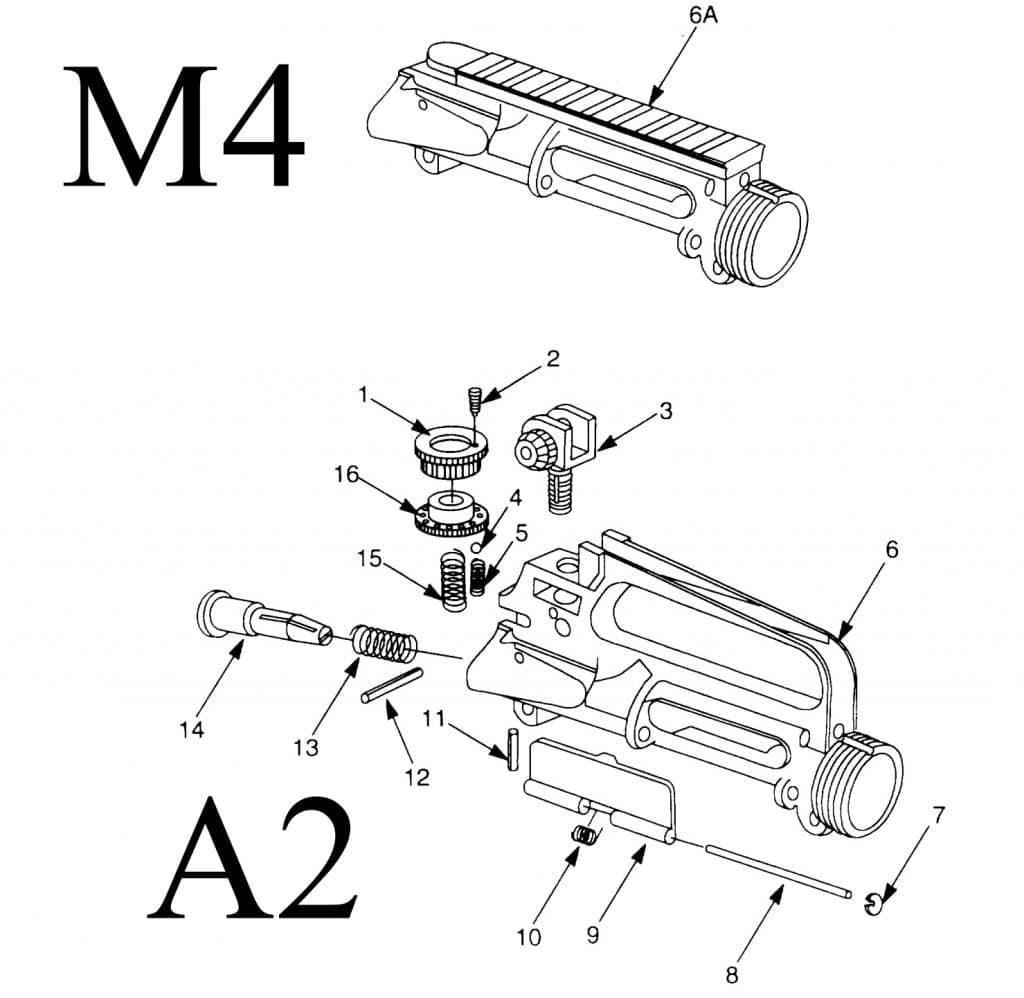

A1 Uppers

The original AR15/M16 style A1 uppers first appeared in the 1960s, courtesy of Colt, when the rifle was being used in Vietnam.

Differing from Stoner’s original design, it had a forward assist (on insistence from the Army), used a light profile 20-inch “pencil barrel” (0.625-inch diameter) with a 1:12 twist, and had a fixed carrying handle that doubled also housed the rear sight.

It used a rifle barrel extension. Very early slab-sided uppers, such as those seen on the Colt 602 series, lacked the provision for a forward assist.

A2 Uppers

The A2 upper style popped up in the early 1980s when Colt answered a request by the Army to update the design to a heavier barrel with a 1:9 (or 1:7) twist rate that was thicker in front of the front sight.

It ditched the Vietnam-era triangular “Mattel” handguard with a rounded one and moved away from the birdcage-style of flash hider to a cage-style muzzle device (closed on the bottom). It still had the fixed carrying handle, but it included a much better rear sight.

It also added a spent case deflector.

On the consumer market at the time, Colt also did the whammy that was using what was known at the time as “small hole” upper receivers with a sear relief and a .250-inch diameter “mil-spec” front lug for military/LE contracts and a .315-inch “big hole” front lug on the upper and lower for the consumer market, so that Mil/LE uppers couldn’t be used on “civilian” lowers.

Today, almost every upper on the consumer market– save for old Colts and some retro builds– are “small hole” on both the front and rear lug and will accommodate a “full-auto” bolt carrier group although the use of the latter does not make the AR it is used on into a select-fire gun.

A3 Uppers

The A3 upper appeared shortly after the A2 but was the first “flat-top” style, losing the carrying handle in favor of a top accessory rail. Generally, these were Weaver-style rails while today Picatinny (MIL-STD-1913, adopted in 1995) is standard.

Of note, Weaver rails have .180-inch wide slots and do not have consistent spacing between the grooves while Picatinny slots are a more precise .206-inches wide with a center-to-center groove width of .394-inches.

As a rule of thumb, Weaver accessories will usually fit on Pic rails while Pic rail accessories will usually only fit a Pic rail. Typically, on today’s commercial market, a true A3 rifle upper is rare.

A4 & M4 Uppers

A4/M4 uppers hit the market in a confusing way as they came from two different branches of the same family tree. Colt developed the M16A4 in the mid-1990s for the Marines, generally using a 20-inch 1:7 barrel with a flat-top MIL-STD-1913 receiver and a handguard with an M5 Adapter Rail System.

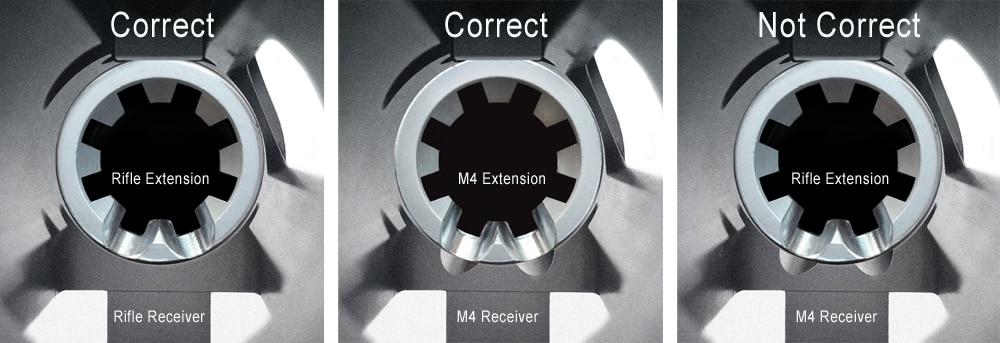

Meanwhile, the M4 was developed to run a shorter 14.5-inch barrel length and a collapsible stock. The M4 included a feed ramp extension that helped with feeding ammo at high rates of fire when coupled with a shorter carbine-length (vs a mid length gas system) the latter of which presented more occasions when a cartridge tried to load in a more “tip down” fashion than normal, leaving the bullet tip to strike the flat surface of the upper receiver, just below the standard rifle feed ramp and thus causing a jam.

The M4’s feed ramp extension was meant to fix that.

Today, most commercial suppliers use the technically incorrect term (when compared to military designations) “A4” or “A3” simply to describe a flat-top upper receiver with no M4 feed ramp extensions and “M4” to describe a flat-top upper with M4 feed ramps cut into the upper– although some advertised as A3/A4 uppers will confusingly have M4 feed ramps, blurring the line between the types greatly. Typically, both styles will have the Forward Assist, run a Pic top rail with RIS T-markings, be finished with a black hard coat anodized coating, and have an integral brass deflector. This has often become the default industry standard, which is a good thing as it allows a lot of options.

Remember though, kids, all ARs have feed ramps cut in the barrel extension. The M4 feed ramp just allows the cartridge to ride a little extra jump from the upper to the barrel extension.

This presents the mix-and-match scenario where a builder is usually fine with using an M4 style upper with a barrel that includes an M4 style extension, or with an M4 barrel on an A1/A2/A3/A4 upper without M4 feed ramps, but not a standard barrel on an M4 receiver as the ramps will more than likely not match up.

Why swap to or use an M4 Upper?

It boils down to the best option for reliability and standards. Sure, there are tons of perfectly functional old A1/A2 uppers out there– watch out for “big holes”– and if you are into the carry handle game that is nice for a retro build.

The A3 upper is a flattop but you don’t get the extra feed ramp “bite” that the M4 offers, and you also run the risk of getting some funky Weaver rail (especially on an older upper) instead of a Pic rail. The A4 gets you closer to right as at least you are guaranteed a Pic rail rather than Weaver, but you do not have the extra feed ramp extension of the M4.

With the M4 upper, you get the whole package: forward assist, brass deflector, flat-top with a Pic rail, and a feed ramp extension that helps with reliability–especially if not using a rifle-length gas system.

Plus, if using a larger bullet weight than typical a few years ago (i.e., 77-grain), since the tip of the bullet often sits lower to the centerline of the bore, that extra bit of ramp helps.

In this respect, the M4 is a minor improvement over the standard M-16s and AR-15s that came before it.

In short, you do not have to go with an M4 upper, but for most general-purpose non-retro builds it just makes sense. Further, it is rare now to find an upper receiver or a ready-to-go barrel that doesn’t have the M4 ramp cuts– which is important as feeding issues can arise when receivers and barrel extensions are mismatched.

M4 Upper Selection Considerations

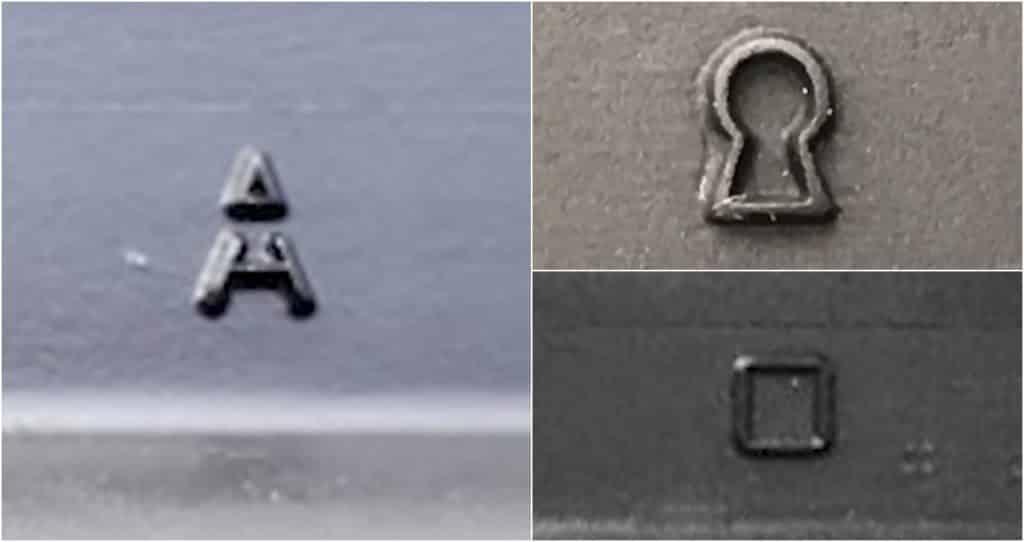

Upper Forge Markings

Multiple forges produce aluminum receiver blank blocks for the firearms industry. These blanks are bought by firearm/receiver makers and milled out to varying standards to produce a finished product.

Typically, these forges leave their own proof marks on their blanks (keyhole: CFP, square: BAFE, splintered arrow: Anchor Harvey). Do not get too wrapped up in who forged the blocks, as often firearm/receiver makers will source their blanks from different forges throughout the years and you can often even find different forge marks on receivers in the same shipment.

It is the final manufacturer– the folks that mill out the Pic rails, extensions, and ramps– that ensures their level of precision and quality control. We’ll talk about some of the best M4 upper manufacturers later in this article.

Materials

Unlike lowers– which include some examples made of polymer or stainless steel– about every serious AR-style upper we have ever come across is made of aluminum.

This means T6-tempered 6061 or 7075 series aerospace aluminum with the latter, 7075-T6, being the most preferred and common these days.

In the match-off between the two grades, 7075 is harder and stronger, leading to better tensile strength, fatigue strength, and shear strength compared to 6061. Most makers these days reserve 6061 for use as handguard materials and in charging handles, for which it is sufficiently strong.

Construction

There are also three separate ways of making uppers: cast (poured into a mold), forged (aluminum block hammered into shape), and billet (an aluminum block carved into its final shape by a CNC machine).

Of these, the cast type is the worst, as the process is prone to making a more brittle finished product due to inherent imperfections in the casting process.

Billet is the most expensive as it requires the most machining but produces the most aesthetically-pleasing designs. Forged uppers split the difference while providing a strong component for a decent price.

Professionally completed forged or billet uppers made of decent quality 7075-T6 will basically last forever– provided properly loaded ammo is used and in-spec parts are installed on it– and can outlast several barrels and bolt carrier groups.

Tolerance stacking

A problem can occur when an M4 barrel– even a good-quality M4 barrel– and an M4 upper– even a good-quality M4 upper– will not mesh together properly.

This is when, for instance, the feed ramp of the barrel extension ramps overhangs the feed ramp extension of the receiver, producing a stop or ledge where the two meet. In situations like this, the receiver may have to be recontoured to mesh with the barrel seamlessly as the individual tolerances of the components, while they may have been superb by themselves, are out of range when mated.

If suffering feeding issues on your new M4 build, such as nosediving, odds are you may want to check for this fitment between the two components. One way around this is to get an M4 upper that already has the barrel installed and tested by the manufacturer, thus in theory evening out the feed ramps.

Sources

- ATF, Firearms Commerce in the United States, 2011, Pg 22

Sign up for our newsletter

Get discounts from top brands and our latest reviews!