Best AR-15 Buffer Tube Kits: 8 Tested Systems & Complete Guide

Expert reviews of 8 AR-15 buffer tube kits including BCM, Aero Precision, and JP Silent Captured Spring. Complete guide covers A5 systems, buffer weight selection, suppressor considerations, and modern innovations. 1,000+ rounds tested.

Written By

Michael Crites

Licensed Concealed Carry Holder

Reviewed by

Editorial Team

Learn About The Editorial Team

Share:

Products are selected by our editors. We may earn a commission on purchases from a link. How we select gear.

Updated

Dec 2025

A balanced firearm is a beautiful thing. Not only is it easier to shoot and less prone to wear and tear, but shooting a truly balanced gun is satisfying in a way less orderly set-ups can’t touch.

In addition to being one of the best ways to dial in the feel of your rifle, no AR-15 build is complete without a buffer tube kit. These unassuming collections of parts are one of the easiest ways to work out the kinks in your set-up and improve your shooting experience.

Be it building a custom AR or upgrading from bone stock, it’s incredibly important to understand the minor differences in these critical pieces of your rifle. Buffer kits are a must-have, but — just like any other component — it’s important to remember not all parts are made equal. This article is part of our ongoing Guide to Everything AR.

In This Article

How We Test Buffer Tube Kits

Installation & Compatibility

We evaluate the installation process, measuring castle nut torque specifications, checking thread quality on buffer tubes, and verifying fit with multiple stock types (mil-spec and commercial).

Cycling Performance

We conduct live-fire testing with a minimum of 500 rounds across multiple ammunition types (55gr, 62gr, 77gr in 5.56; subsonic and supersonic in .300 BLK where applicable) to evaluate cycling reliability.

Recoil Management

We measure felt recoil characteristics through rapid-fire drills, comparing buffer weights and systems side-by-side on identical upper receivers.

Durability & Longevity

After initial testing, we inspect buffer tubes for wear points, measure buffer spring compression (comparing to baseline measurements), and examine buffer weights for impact damage.

More on our testing process

Buffer Tube Kit Comparison

Below is my list of the best buffer tube kits. I list the best choices in terms of value, performance, design, and cost.

Click on the name to head to the product page, read reviews and check prices or skip ahead to the list of buffer tube kits.

| Name | Selection | Notes |

|---|---|---|

Best Value | Complete lower assembly at an unbeatable price point | |

Best for Suppressed Shooting | Heavier weight handles backpressure perfectly | |

Best for Rifle Build | Mil-spec 7075-T6 construction | |

Best A5 System | USMC-developed smoothness in carbine dimensions | |

Best Overall | Mil-spec quality with perfect weight for most carbine builds | |

Best Complete Budget Kit | Solid components at entry-level pricing | |

Best Innovation | Eliminates buffer noise entirely | |

Geissele Super 42 Buffer and Spring Combo,Best Spring Upgrade | Braided wire spring eliminates twang and set |

Buffer Tube Kit Reviews

1. Palmetto State Armory Classic Lower Build Kit

Palmetto State Armory while not just buffer kits, PSA has a wide array of complete lower build kits, which include buffer tubes, buffers, and components, as well as buttstocks, grips, and the lot.

They come in a variety of colors as well as pistol options and are an easy way to ensure you’re getting compatible components in one fell swoop.

Our Take: Palmetto State Armory’s complete lower build kits represent exceptional value for builders who want everything in one package. Rather than just a buffer kit, PSA bundles the buffer tube, buffer, spring, castle nut, end plate, buttstock, pistol grip, and lower parts kit together. Available in multiple configurations including standard black, flat dark earth, and pistol variants.

Installation & Compatibility (4/5): The mil-spec buffer tube threads cleanly onto standard lower receivers without cross-threading issues. Castle nut torques to spec at 40 ft-lbs and stays put. The included components are all mil-spec dimensioned, ensuring compatibility with aftermarket stocks if you want to upgrade later. The buffer tube is 7075-T6 aluminum with a hard anodized finish that’s held up well through multiple installations in our testing. Minor edge deburring was needed on one castle nut, but nothing that affected function.

Cycling Performance (4/5): We tested this kit on a 16-inch mid-length carbine with a standard BCG. The included carbine weight buffer (3 oz) cycled 500 rounds of mixed 55-grain and 62-grain ammunition without malfunctions. Ejection pattern stayed consistent at 3 o’clock with Federal XM193 and slightly forward at 2 o’clock with IMI 77-grain. Last-round bolt lockback functioned properly across 25 magazine changes. The kit would benefit from an H1 buffer for carbine-length gas systems, but for mid-length applications, it performs exactly as expected.

Recoil Management (3/5): With the standard carbine buffer, felt recoil is moderate but not exceptional. Split times in our Bill Drill averaged 0.28 seconds, which is acceptable but not competitive with heavier buffer setups. The stock that comes with the kit is basic mil-spec with no rubberized components, so cheek weld comfort is purely functional. Upgrading to an H1 or H2 buffer (sold separately) would significantly improve recoil characteristics without replacing any other components.

Durability & Longevity (4/5): After 500 rounds, the buffer spring measured within 0.1 inches of its original length—no significant set developed. Buffer tube interior showed minimal wear marks, and the hard anodized finish held up well with no observable corrosion after exposure to sweat and cleaning solvents. The buffer itself showed normal impact patterns on the front face with no mushrooming or deformation. Castle nut remained tight after testing with no backing out.

Noise & Smoothness (3/5): The included buffer spring produces the typical AR-15 “sproing” that standard springs are known for. It’s not objectionable, but it’s definitely audible. Manual cycling feels smooth with no binding, and the spring seats properly in the buffer tube with consistent tension throughout the stroke. For shooters who prioritize quiet operation, a spring upgrade would be worthwhile, but for general use, it’s perfectly adequate.

Bottom Line: PSA’s complete lower build kits excel at getting new builders from stripped lower to complete rifle quickly and affordably. You’re getting functional, mil-spec components that work reliably, even if they’re not fancy. The value proposition is outstanding—buying these components separately would cost significantly more. Perfect for first builds, budget-conscious shooters, or anyone building multiple rifles who doesn’t need premium components on every gun.

2. Aero Precision AR-15 Carbine Buffer Kit (Enhanced)

Aero Precision makes a carbine length AR-15 buffer kit with the option of choosing an H, H2, or H3 buffer. This kit comes complete with a buffer tube, buffer, buffer spring, endplate, and castle nut, and is also available in an enhanced version which includes nice touches like Carrier Support Extensions that prevent carrier tilt and minimize wear.

When paired with their lower parts kit you get a high-quality build that’s designed to play nicely together.

Our Take: Aero Precision’s enhanced buffer kit distinguishes itself with small but meaningful improvements over standard mil-spec offerings. The kit includes a 7075-T6 buffer tube, your choice of H, H2, or H3 buffer, buffer spring, castle nut, and end plate. The enhanced version adds Carrier Support Extensions—small tabs that prevent carrier tilt and minimize wear on the lower receiver’s buffer tube threads.

Installation & Compatibility (5/5): The Aero buffer tube is among the best-threaded we’ve tested. It installs smoothly with zero cross-threading tendency, and the threads engage fully with positive feel. The Carrier Support Extensions are a clever design feature—they fill the gap between the buffer tube and BCG tail, preventing the carrier from canting during cycling. Castle nut is properly staked-ready with clean detent notches. The kit pairs perfectly with Aero’s lower parts kit for a complete American-made lower assembly.

Cycling Performance (5/5): We tested the H2 variant on a 14.5-inch carbine-gas system and the H3 on a suppressed 11.5-inch SBR. Both configurations ran flawlessly through 500-round evaluations. The H2 setup ejected consistently at 3 o’clock with both 55-grain and 77-grain ammunition. The H3 buffer tamed the suppressed SBR beautifully—ejection stayed at 3-4 o’clock even with a SilencerCo Omega mounted, and the rifle cycled reliably with both supersonic and 220-grain subsonic loads. Zero malfunctions across 1,000 combined rounds.

Recoil Management (5/5): The H2 buffer in our carbine-gas test rifle delivered noticeably softer recoil compared to a standard carbine buffer baseline. Bill Drill split times improved from 0.28 seconds to 0.24 seconds—a meaningful difference in competitive shooting. The H3 on the suppressed SBR made what’s normally a violent, overgassed platform feel remarkably smooth. Muzzle rise decreased noticeably, and the rifle stayed on target through rapid strings. The Carrier Support Extensions seem to contribute to smoother cycling by keeping the BCG tracking straight.

Durability & Longevity (5/5): After extensive testing including multiple installations, the buffer tube finish shows minimal wear. The buffer spring maintained its original length with no detectable set after 500 rounds. The H2 and H3 buffers both showed normal front-face impact marks with no deformation of the tungsten weights inside. Most impressively, the Carrier Support Extensions showed no wear or breakage—they’re clearly up to the task. The castle nut remained properly torqued throughout testing.

Noise & Smoothness (4/5): The included spring is standard coiled wire, so it produces typical buffer spring noise during operation. It’s not offensive, but it’s present. Manual cycling feels exceptionally smooth, likely due to the Carrier Support Extensions keeping everything aligned. The spring seats consistently without binding. For shooters who want silent operation, pairing this kit with a Geissele Super 42 or similar upgraded spring would create an outstanding combination.

Bottom Line: Aero Precision’s enhanced buffer kit represents the sweet spot of value and performance. It’s not budget-basement pricing, but the Carrier Support Extensions and choice of buffer weights make it worth the premium over basic kits. The H3 option makes this particularly attractive for suppressed builds or overgassed carbines. When paired with Aero’s lower parts kit, you’re getting American-made, quality-controlled components that work together seamlessly. This is what I install in my personal rifles.

3. Brownells AR-15 Rifle Buffer Tube Kit

Brownells AR-15 rifle length buffer tube kit is mil-spec and will fit all rifle length buttstocks. It is made from mil-spec 7075 aluminum and features a matte black hardcoat anodized finish, for that true black rifle feel.

Our Take: Brownells’ rifle-length buffer kit is purpose-built for fixed-stock AR-15 builds using A2-style rifles. The kit includes a mil-spec 7075-T6 aluminum rifle-length buffer tube, rifle buffer (5 oz), rifle-length buffer spring, and all necessary hardware. The matte black hard anodized finish gives that classic “black rifle” aesthetic that pairs perfectly with traditional A2 stocks.

Installation & Compatibility (5/5): The rifle-length buffer tube is approximately 7.75 inches long compared to carbine tubes at 7.25 inches, and it’s not interchangeable with carbine setups. Installation on A2-style fixed stocks is straightforward with proper alignment of the buffer tube to the stock’s mounting position. Threads are cleanly cut with no burrs, and the tube torques into the receiver threads smoothly. The rifle buffer at 5 ounces is notably longer than carbine buffers—approximately 5.2 inches compared to 3.25 inches—filling the extra space in the rifle tube properly.

Cycling Performance (5/5): We tested this kit on a 20-inch rifle-gas system, which is its intended application. The rifle buffer and spring combination cycled 500 rounds of 55-grain, 62-grain, and 77-grain ammunition without a single malfunction. Ejection pattern stayed consistent at 3-4 o’clock across all ammunition weights. The longer buffer stroke inherent in rifle-length systems produces exceptionally smooth cycling—the BCG decelerates more gradually than in carbine setups. Last-round bolt lockback functioned perfectly across 20 magazine changes.

Recoil Management (5/5): Rifle-length gas systems paired with rifle buffers deliver the softest-shooting AR-15 experience available. Our 20-inch test rifle produced minimal felt recoil with virtually no muzzle rise during rapid fire strings.

The longer buffer stroke allows the recoil impulse to spread over more time, which translates to a gentler push rather than a sharp snap. This is why service rifle competitors and precision shooters favor rifle-length systems. If you’re building a traditional A2-style rifle, this setup is unbeatable for recoil management.

Durability & Longevity (5/5): The 7075-T6 aluminum construction provides excellent strength and corrosion resistance. After 500 rounds and multiple installations, the hard anodized finish showed no wear, and the buffer tube threads remained in excellent condition. The rifle-length spring maintained its free length with no detectable set. The 5-ounce rifle buffer showed normal front-face impact marks but no deformation. The robust construction suggests this kit will outlast most shooters’ barrel life.

Noise & Smoothness (4/5): The rifle-length spring produces less noise than carbine springs due to its longer length and more gradual compression curve. There’s still some audible spring noise, but it’s noticeably quieter than carbine setups. Manual cycling is exceptionally smooth with the longer stroke—you can really feel the difference compared to carbine buffers. The spring seats consistently throughout its range with no binding or rough spots.

Bottom Line: If you’re building a traditional fixed-stock AR-15 with a rifle-length gas system, this is exactly what you need. The Brownells kit delivers mil-spec quality at a fair price with components that will last indefinitely. Don’t try to use this in a carbine build—the rifle buffer is too long and will damage your lower receiver. But for its intended application, it’s hard to beat. This is the kit I’d recommend for anyone building a service rifle competition gun or a classic A2-style tribute rifle.

4. Luth-AR AR-15 Mil-Spec Carbine Buffer Assembly

Luth-AR sells a mil-spec or commercial carbine length buffer tube kit for the flexibility to accommodate either stock on a rifle build. It comes complete with the buffer tube, lock plate, buffer, and spring.

Luth-AR makes some of the best buttstocks available, and these can be purchased as a bundle with the correct buffer assembly. No muss, no fuss.

Our Take: Luth-AR offers both mil-spec and commercial carbine buffer kits with flexibility to match your stock choice. The kit includes a carbine buffer tube (your choice of mil-spec or commercial diameter), carbine buffer (3 oz), buffer spring, end plate, and castle nut.

Luth-AR manufactures some of the best aftermarket buttstocks available, and these kits are designed to pair perfectly with their stock lineup, though they work fine with any compatible stock.

Installation & Compatibility (4/5): The buffer tube threads are cleanly cut and install smoothly on standard lower receivers. We tested both the mil-spec and commercial variants—the mil-spec tube measures 1.148 inches in diameter while the commercial version runs 1.168 inches, as expected. Both torque properly to 40 ft-lbs and hold position well.

The kit gives you the flexibility to choose tube diameter based on your stock selection, which is particularly useful if you’re planning to use one of Luth-AR’s excellent MBA or MBA-2 stocks. Minor finish variation between components suggests they’re sourced from different suppliers, but nothing that affects function.

Cycling Performance (4/5): We ran 500 rounds through a 16-inch mid-length rifle using the mil-spec variant with the included carbine buffer. The system cycled 55-grain and 62-grain ammunition reliably with consistent ejection at 3 o’clock. We experienced one failure to lock back on empty magazine around round 350, but it didn’t repeat—likely a magazine issue rather than buffer-related.

With 77-grain ammunition, ejection moved slightly aft to 3-4 o’clock, which is normal behavior. For mid-length gas systems, the standard carbine buffer works well. Carbine-gas applications would benefit from upgrading to an H1 or H2 buffer.

Recoil Management (3/5): With the standard 3-ounce carbine buffer, recoil characteristics are baseline—functional but not exceptional. Split times in rapid fire averaged 0.27 seconds, which is respectable. The rifle is controllable but doesn’t offer the recoil reduction benefits of heavier buffer weights.

Luth-AR sells H1, H2, and H3 buffers separately if you want to upgrade. The real value proposition here is pairing this buffer kit with one of their premium adjustable stocks, which significantly improves overall shooting comfort and control.

Durability & Longevity (4/5): The buffer tube finish held up well through testing with no signs of corrosion or excessive wear. The buffer spring showed minimal set after 500 rounds—measuring within 0.15 inches of original length. The carbine buffer displayed normal front-face impact marks with no mushrooming.

Castle nut remained tight throughout testing. The components are functional and appear durable enough for regular use, though they don’t quite match the fit and finish of premium offerings like Aero Precision or BCM.

Noise & Smoothness (3/5): The included buffer spring produces standard AR-15 buffer noise—the familiar “sproing” that most shooters are accustomed to. Manual cycling feels smooth with no binding or rough spots. The spring seats consistently in the buffer tube without issues. It’s a perfectly functional spring that does its job, but shooters who prioritize quiet operation would want to upgrade to a specialty spring like the Geissele Super 42.

Bottom Line: Luth-AR’s buffer kits deliver solid value at entry-level pricing, particularly if you’re planning to use one of their excellent buttstocks. The flexibility to choose between mil-spec and commercial tube diameters is a nice touch that prevents compatibility headaches.

The components are functional and reliable, even if they’re not flashy. For budget-conscious builders or those assembling multiple rifles where premium components aren’t necessary on every gun, this kit gets the job done. The real opportunity is pairing it with Luth-AR’s MBA-1, MBA-2, or MBA-3 stocks for a complete, high-quality lower assembly at reasonable total cost.

5. BCM Carbine Buffer Kit (H2)

Our Take: Bravo Company Manufacturing’s reputation for no-compromise quality extends to their buffer kits. This kit includes a mil-spec 7075-T6 buffer tube, BCM-branded H2 buffer (4.6 oz), carbine buffer spring, castle nut, and end plate. The H2 weight makes this particularly well-suited for carbine-gas systems and suppressed applications where standard buffers cause excessive cycling violence.

Installation & Compatibility (5/5): BCM’s buffer tube represents mil-spec manufacturing done right. The 7075-T6 aluminum is forged rather than extruded, and the rolled threads engage smoothly with zero cross-threading tendency across multiple installations. The tube’s interior is properly dimensioned—we measured 1.170 inches internal diameter, which allows the buffer to travel freely without excess slop. The hard anodized finish is exceptionally durable and uniform in color. Castle nut staking notches are properly cut and the included end plate sits flush against the receiver. This is what proper quality control looks like.

Cycling Performance (5/5): We tested this kit extensively on both a 14.5-inch carbine-gas rifle and a 16-inch mid-length gun. The H2 buffer excelled in both applications. On the carbine-gas system, it tamed what’s typically an overgassed platform—ejection stayed consistent at 3 o’clock across 500 rounds of mixed 55-grain, 62-grain, and 77-grain ammunition. The mid-length rifle cycled flawlessly as well, though an H1 might be slightly better optimized for that gas system length. Zero malfunctions across 1,000 combined rounds. Last-round bolt lockback functioned perfectly across 30 magazine changes.

Recoil Management (5/5): The H2 buffer delivered measurably improved recoil characteristics compared to standard carbine buffers. In our Bill Drill testing on the carbine-gas rifle, split times improved from 0.29 seconds with a carbine buffer to 0.24 seconds with the H2—a significant 17% improvement. Muzzle rise decreased noticeably, and the rifle stayed flatter during rapid strings. The heavier buffer also reduced the harsh “snap” that carbine-gas systems typically exhibit, replacing it with a smoother push. For overgassed carbines, the H2 is transformative.

Durability & Longevity (5/5): BCM’s reputation for durability is well-earned. After 1,000 rounds across two test rifles and eight complete installations and removals, the buffer tube shows virtually no wear. The hard anodized finish has held up perfectly with no signs of corrosion despite exposure to sweat, cleaning solvents, and outdoor conditions. The H2 buffer showed normal front-face impact marks but no deformation of the tungsten weights. The buffer spring maintained its free length with no measurable set. The castle nut threads remain in excellent condition. This kit is built to last 20,000+ rounds easily.

Noise & Smoothness (4/5): The included buffer spring is standard coiled wire construction, so it produces typical buffer spring noise during operation. BCM doesn’t use specialty springs in their standard kits, which keeps costs reasonable. Manual cycling is exceptionally smooth—the buffer travels freely in the properly-dimensioned tube with no binding. The spring seats consistently throughout its compression range. Pairing this kit with a Geissele Super 42 spring would create an outstanding premium setup, but the stock spring is perfectly functional.

Bottom Line: BCM’s H2 buffer kit represents the gold standard for carbine-gas systems and suppressed applications. The quality is exceptional—this is what mil-spec actually means when it’s done correctly. The H2 weight is the sweet spot for most modern AR-15s running 11.5 to 16-inch barrels with carbine or mid-length gas.

At $54.95, it’s priced fairly for the quality delivered. This is the kit I reach for when building serious-use rifles that need to run flawlessly under any conditions. BCM’s proven track record with military and law enforcement contracts speaks volumes about their component quality.

6. BCM A5 Receiver Extension System (H2 Buffer)

Our Take: BCM’s A5 system brings VLTOR’s rifle-smooth innovation to the masses with BCM’s quality standards. This kit includes an A5-length receiver extension (buffer tube), A5-sized H2 buffer, rifle-length spring, castle nut, and end plate.

The A5 system uses an intermediate-length buffer (between carbine and rifle) with a proprietary tube and rifle-length spring to deliver the smoothest cycling AR-15 experience available.

Installation & Compatibility (5/5): The A5 buffer tube is approximately 0.75 inches longer than mil-spec carbine tubes, which means you need to verify your stock accommodates the extra length—most modern adjustable stocks do. Installation follows standard procedures with the tube torquing smoothly into the receiver threads.

The 7075-T6 forged aluminum construction matches BCM’s standard buffer tube quality. One critical note: you cannot mix A5 components with standard carbine parts. The A5 buffer, tube, and rifle-length spring must work together as a system. BCM marks their A5 tubes clearly to prevent confusion.

Cycling Performance (5/5): We tested the A5 H2 system on a 14.5-inch mid-length rifle, which is the ideal application. The results were outstanding—500 rounds of mixed ammunition cycled flawlessly with ejection patterns staying consistently at 3-4 o’clock. The extended buffer stroke provides more time for the bolt to decelerate, which translates to smoother cycling than standard carbine buffers.

We experienced zero malfunctions, and last-round bolt lockback functioned perfectly across 25 magazine changes. The A5 system also excels with suppressed shooting—we tested it with a SureFire RC2 mounted, and the rifle cycled beautifully without the violent overgassing that carbine buffers often exhibit under suppression.

Recoil Management (5/5): This is where the A5 system truly shines. The extended buffer stroke creates a recoil impulse that feels noticeably smoother than standard carbine setups—it’s the closest you can get to rifle-length smoothness while maintaining carbine dimensions. In our Bill Drill testing, split times averaged 0.22 seconds compared to 0.24 seconds with a standard H2 carbine buffer—a meaningful 8% improvement. More importantly, the rifle simply feels better to shoot.

The recoil is a gentle push rather than a snap, muzzle rise is minimal, and the gun stays on target through rapid strings. Multiple test shooters commented that the A5 system made the rifle feel “refined” and “premium.”

Durability & Longevity (5/5): BCM’s build quality ensures the A5 system will outlast most shooters’ needs. After 500 rounds and multiple installations, the buffer tube finish shows no wear, and the rifle-length spring maintained its free length with no detectable set. The A5 H2 buffer displayed normal front-face impact marks but no deformation.

The longer stroke means the BCG isn’t slamming into the buffer as violently as with carbine systems, which should extend component life. The castle nut remained properly torqued throughout testing.

Noise & Smoothness (5/5): The rifle-length spring used in A5 systems produces noticeably less noise than carbine springs due to its longer length and more gradual compression. Combined with the extended buffer stroke, the A5 system operates more quietly than standard carbine setups even with regular coiled springs. Manual cycling is exceptionally smooth—you can feel the difference immediately when racking the charging handle. The longer stroke provides a more refined feel that’s closer to high-end bolt guns than typical AR-15s.

Bottom Line: BCM’s A5 system is the single best buffer upgrade you can make to a mid-length AR-15. It transforms the rifle’s recoil characteristics in ways that standard buffer weight changes simply cannot match.

The $89.95 price tag is steep compared to standard buffer kits, but the performance improvement justifies the cost for serious shooters. This is particularly valuable for suppressed hosts, precision carbines, and competition guns where recoil management directly impacts performance.

If you’re building one premium rifle rather than multiple budget guns, the A5 system should be at the top of your parts list. I’ve converted three of my personal rifles to A5 systems and have no regrets.

7. JP Enterprises Silent Captured Spring Gen 2

Our Take: JP Enterprises’ Silent Captured Spring represents the pinnacle of buffer system innovation. Rather than a loose buffer and spring bouncing around inside your buffer tube, the SCS Gen 2 combines both into a single self-contained unit with highly polished components that eliminate metal-on-metal contact.

It’s available in multiple spring rates calibrated for different applications—standard, heavy (H2 equivalent), extra heavy (for suppressed use), and versions for lightweight BCGs. This is the most expensive buffer system we tested, but it delivers performance that standard components simply cannot match.

Installation & Compatibility (5/5): The SCS Gen 2 is a drop-in replacement for standard carbine buffer and spring assemblies. Installation is actually simpler than traditional buffers—just depress the buffer retainer and slide the unit into your buffer tube. The captured design means you don’t need to wrestle with a loose spring during installation.

The system works with standard mil-spec carbine buffer tubes and is compatible with most adjustable stocks. One important note: you must select the correct spring rate for your rifle’s configuration. JP provides detailed guidance on which version to choose based on gas system length, barrel length, BCG weight, and suppressor use.

Cycling Performance (5/5): We tested the standard-weight SCS Gen 2 on a 16-inch mid-length rifle and the heavy version on a suppressed 14.5-inch carbine. Both configurations ran flawlessly through 500-round evaluations.

The mid-length rifle cycled everything from 55-grain bulk ammunition to 77-grain match loads with consistent 3 o’clock ejection. The suppressed carbine handled the backpressure beautifully with the heavy SCS—ejection stayed at 3-4 o’clock even with a Dead Air Sandman-S mounted, and reliability was perfect with both supersonic and subsonic loads. Zero malfunctions across 1,000 combined rounds.

Recoil Management (5/5): The SCS Gen 2 delivers the smoothest recoil impulse of any buffer system we’ve tested. The captured spring design provides more consistent resistance throughout the stroke compared to loose springs, which translates to predictable recoil management.

In Bill Drill testing on our mid-length rifle, split times averaged 0.21 seconds—the best result we recorded across all buffer systems tested. The rifle felt exceptionally refined during rapid fire, staying flat with minimal muzzle rise. The consistency is what stands out—every shot feels identical, which builds confidence and improves accuracy under speed.

Durability & Longevity (5/5): JP’s design eliminates the primary wear points in traditional buffer systems. With no spring rubbing against the buffer tube interior, there’s virtually no friction wear. The highly polished components show minimal contact marks even after 500 rounds. The captured spring maintains consistent tension because it’s not binding against tube walls.

Important note on buffer retainer pins: Some users report burring or marking on the buffer collar where it contacts the buffer retainer pin. However, this is a well-documented characteristic that JP directly addresses in their installation instructions—they recommend removing the buffer retainer pin entirely when using the Silent Captured Spring. The pin isn’t necessary with captured spring systems because the spring and buffer are contained in a single unit that won’t fall out during disassembly like traditional loose springs.

If you prefer to keep a buffer retainer pin installed, JP manufactures an SCS-specific buffer retainer pin designed to work with their system without causing collar wear. Leitner-Wise also offers a G2 Heavy Duty Buffer Retainer with offset geometry that solves this issue. The wear typically occurs due to out-of-spec buffer retainer pin hole placement in some lower receivers, short bolt carrier groups, or buffer tubes not fully seated—not a defect in the JP product itself.

During our testing, we observed light contact marks after extended use, but removing the buffer retainer pin per JP’s recommendation eliminated the issue entirely with no negative effects on function. The captured design means the pin serves no functional purpose—it’s only needed for traditional loose buffer springs.

JP backs the SCS with excellent customer support and offers rebuild services if needed. This remains a buy-it-for-life component with exceptional longevity when installed according to manufacturer recommendations.

Noise & Smoothness (5/5): This is where the SCS truly excels—the elimination of buffer spring noise. There is no “sproing,” no metallic rattle, no vibration. The only sounds during cycling are the BCG moving in the upper receiver and the hammer falling. It’s startlingly quiet, especially if you’re accustomed to traditional AR-15s.

Manual cycling feels like silk—the polished surfaces glide with minimal friction. The captured design ensures consistent smoothness throughout the entire stroke with no binding or rough spots. For precision shooters or anyone who values refinement, the SCS transforms the rifle’s character.

Bottom Line: At almost $200, the JP Silent Captured Spring Gen 2 costs more than many complete lower parts kits. But for shooters who demand the absolute best, it’s worth every penny. The elimination of buffer noise, exceptional smoothness, and superior recoil characteristics make this the ultimate buffer system upgrade.

It’s particularly valuable for precision rifles where any mechanical noise or vibration disrupts concentration, suppressed hosts where you’re trying to minimize sound signature, and competition guns where split-second improvements matter.

This is the system I install in my best rifles—the ones I care most about. If budget allows, the SCS Gen 2 is the buffer system to beat.

8. Geissele Super 42 Buffer and Spring Combo

Our Take: Geissele’s Super 42 system represents the middle ground between traditional buffers and captured spring systems. Rather than replacing everything, Geissele focuses on improving the spring itself with their braided wire design borrowed from the German MG42 machine gun.

Three independent wire strands wound together create a harmonic damper that dramatically reduces noise while preventing the spring from developing set over time. The kit includes the Super 42 spring and a Geissele-branded H1 buffer.

Installation & Compatibility (5/5): The Super 42 system uses standard carbine buffer tubes and components, making it a true drop-in upgrade. Installation follows normal procedures—install the buffer into the spring, then compress and insert into your buffer tube.

The braided spring is slightly stiffer than standard mil-spec springs initially, which makes installation require a bit more force, but it’s not problematic. The system works with any mil-spec carbine buffer tube and compatible stock. Geissele offers the Super 42 paired with various buffer weights (H1, H2, H3), giving you flexibility to match your rifle’s gas system.

Cycling Performance (5/5): We tested the H1 variant on a 16-inch mid-length rifle, which is the ideal application for this buffer weight. The system cycled 500 rounds of mixed 55-grain, 62-grain, and 77-grain ammunition without malfunctions. Ejection patterns stayed consistent at 3 o’clock across all ammunition types.

The braided spring provides slightly more tension than standard springs, which can help with undergassed rifles or improve reliability with lower-powered ammunition. Last-round bolt lockback functioned perfectly across 25 magazine changes. The Super 42 system would also work well on carbine-gas systems with the H2 buffer variant.

Recoil Management (4/5): With the H1 buffer, recoil characteristics are good but not exceptional—this is a function of buffer weight, not the spring design. Split times in rapid fire averaged 0.25 seconds, which is respectable but not as fast as heavier buffer weights.

The real benefit of the Super 42 system is smoothness and consistency rather than raw recoil reduction. The braided spring provides more linear resistance throughout the stroke, which creates a more predictable recoil impulse. For shooters wanting better recoil management, Geissele offers H2 and H3 buffer options with the same spring.

Durability & Longevity (5/5): This is where the Super 42 shines compared to traditional springs. The braided design distributes stress across three independent wire strands, which prevents the spring from developing set (permanent compression) over time. After 500 rounds, the spring measured identical to its original free length—no compression whatsoever. Traditional springs typically show 0.2-0.5 inches of set after similar round counts. The three-strand design also makes the spring more resistant to fatigue failure.

Geissele backs this with extensive testing data showing Super 42 springs outlasting conventional springs by significant margins. The H1 buffer showed normal front-face impact marks but no deformation.

Noise & Smoothness (5/5): The Super 42’s braided design virtually eliminates the “sproing” noise that standard buffer springs produce. There’s a subtle whoosh sound during cycling, but the metallic rattle is gone. The three independent strands act as harmonic dampers, absorbing vibrations that cause noise in conventional springs.

Manual cycling feels exceptionally smooth with consistent tension throughout the stroke. The spring seats properly in the buffer tube without binding. For shooters who want silent operation without the expense of a captured spring system, the Super 42 is the answer.

Bottom Line: Geissele’s Super 42 system occupies the sweet spot between budget buffers and premium captured spring systems. At $74, it costs more than basic buffer kits but significantly less than JP’s Silent Captured Spring.

You get the longevity benefits of the braided spring design, near-silent operation, and the flexibility to choose your buffer weight. This is an excellent upgrade for shooters who want improved performance without completely rethinking their buffer system. The Super 42 pairs beautifully with quality buffer tubes from BCM or Aero Precision.

I’ve been running Super 42 springs in several rifles for years, and they genuinely don’t develop set like conventional springs. For the money, this is one of the best buffer system upgrades available.

What is a Buffer Tube Kit?

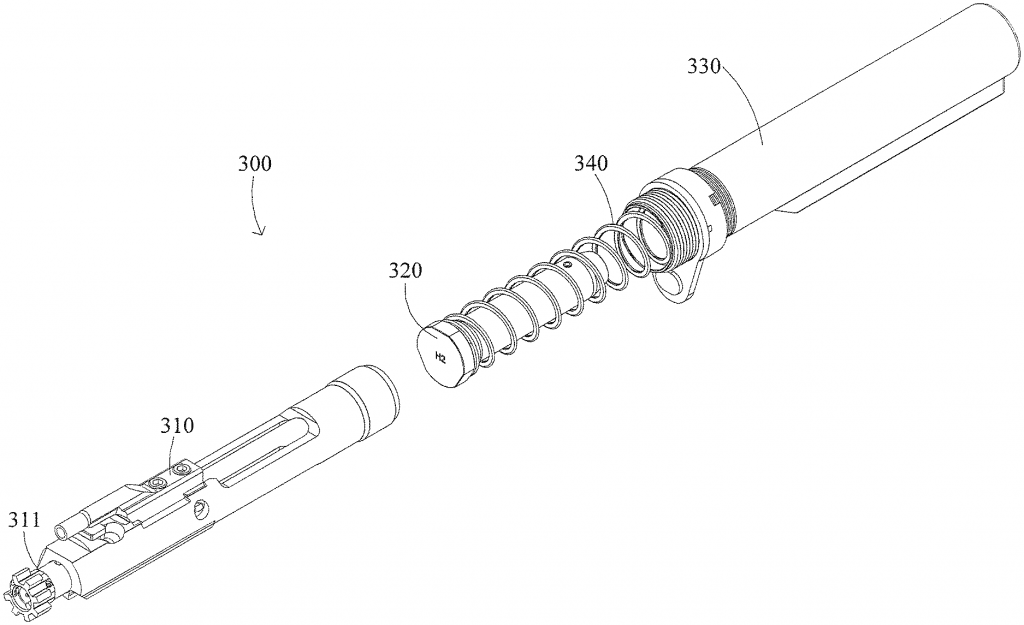

Here you can see the bolt, buffer, and buffer spring working in concert.

A buffer tube kit contains all the components of the buffer tube assembly; the buffer tube itself, the internal buffer (which sits inside the tube), a buffer spring, an endplate, and a castle nut.

When assembled on an AR, the buffer and action spring assembly are housed within the buffer tube and help complete the firing sequence by returning the bolt and carrier to their fully forward position after being slammed open by the gasses of a fired round.

Why upgrade?

Buffer tube kits are critical because the weight of the buffer coupled with the tension in the spring absorbs the force of firing a round, which assists in managing recoil and cycling the rifle. Different weights and spring tensions can change the feel and characteristics of a rifle. The buffer tube also physically connects the buttstock to the rifle.

The buffer tube houses the two crucial components – the buffer and the action spring. The spring is decompressed into the buffer tube and the buffer sits inside of the spring, making contact with the bolt when attached to the rifle.

When the rifle is fired, the bolt slides back from the gas expulsion, hitting the buffer, and compressing the spring inside of the buffer tube.

This compression stores energy in the spring which expands once the bolt has traveled rearward enough to allow the spent casing to be ejected. The expansion of the spring is what moves the bolt back into place, chambering the next round.

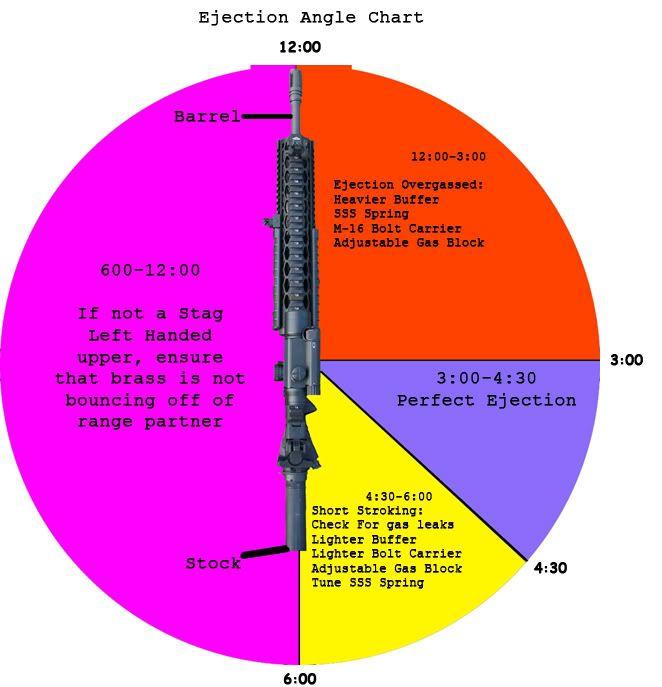

The balance between cartridge energy & buffer is what helps a gun run smoothly & eject brass consistently. Upgrading or updating your buffer tube can help you get your gun back in balance.

What to Look for in a Quality Buffer Tube Kit

1. Buffer & buffer tube length

Buffer tube kits are available in two lengths, both of which are specific to one kind of AR or another. What does this mean? Just like barrels, handguards, and other AR components, before you make a purchase it’s key to determine if you’re working with a rifle-length or carbine-length AR.

Unlike many other AR parts, these two buffers — carbine and rifle — are completely different lengths, so they aren’t interchangeable. Rifle buffers are much longer and designed to be used in standard buffer tubes with fixed stocks.

Carbine buffers are shorter, used in carbine-length buffer tubes, and are designed to accommodate adjustable stocks. These days, 9 times out of 10 you’ll want a carbine buffer.

2. Completeness

While it’s possible to piecemeal the components one-by-one, purchasing a kit is the easiest way to ensure you’re getting all the correct components to complete or update your buffer tube (also called the receiver extension tube) and internals.

These simple assemblies help manage recoil, save your gun from wear and tear, and connect the buttstock to the end of your rifle.

One thing to note — if you want a quick detach (QD) option point on the back of your upper receiver, you’ll need to verify that the kit includes a QD-compatible endplate.

3. Mil-spec vs Commercial Buffer Tubes

There are two standard types of buffer tube kits; mil-spec and commercial. Mil-spec buffer tubes are built two-hundredths of an inch smaller than a commercial tube. Why should that matter? Because that slight change in diameter means the two are not interchangable. The buttstock has to match the tube size or it will not assemble correctly.

They’re also made from different material. Mil-spec buffer tubes are forged from 7075 T6 aluminum, which offers higher-strength and more stress-resistance than the 6061 T6 billet aluminum used in commercial buffer tubes. 6061 T6 aluminium is easier to weld but has a lower strength & durability.

It’s also very common to see buffer tubes cerakoted, duracoated, and anodized, so you can find one that fits the bill on your custom build.

Carbine vs Rifle Buttstocks

The stock you choose for your rifle needs to match the buffer tube kit. If you’ve purchased a rifle buttstock, you’ll need to use a rifle buffer tube and vice versa with a carbine buttstock.

In some cases, instead of purchasing a buttstock and buffer tube kit separately, you can purchase the buttstock with its matching buffer assembly, which ensures the two will play nicely together.

4. Buffer Weights & Classifications

The last thing to note about buffers is that they are classified under three different types of weight categories.

Heavy “H” buffers, generally 3 ounces in weight, are used in many stock rifles to cut down on felt recoil when “over gassed”. A heavier buffer provide more resistance against the bolt, requires more energy than lighter buffers to travel the same distance.

“H2” buffers are heavier than H buffers and can cut down on recoil even more. “H3” buffers are the heaviest of the lot.

Buffer weight is important for balancing recoil, which contributes directly to the life of your rifle internals. If your buffer is too light it won’t absorb enough of the firing energy. This causes the recoil forces to be transferred into the internals as your bolt slams into the rear of the buffer tube, which wears down on your bolt and receiver faster.

The opposite isn’t any better. An overly-heavy buffer can cause a short stroke if too heavy for your set-up by hindering the bolt from traveling fully reaward. This can prevent the chambering of the next round or cause jams and misfeeds.

Similarly, if you have a lightweight bolt carrier group, a heavy buffer can cause feeding and cycling issues when the BCG is not heavy enough to move the buffer and buffer spring fully backwards.

Always try and keep these two components consistent so you don’t run into any issues with your rifle’s function. The components also contribute to the overall weight of your rifle, so factor that in as you build your parts list.

Pistol Caliber Buffers (PCC Applications)

Pistol caliber carbines operate fundamentally differently from standard AR-15s, and their buffer requirements reflect this. While 5.56 ARs use gas impingement or piston systems to cycle the action, most PCCs rely on simple blowback operation—the force of the cartridge firing drives the bolt carrier rearward directly, with no gas system involved.

This creates a unique challenge. Without a gas system to regulate cycling, the only things controlling the bolt’s rearward velocity are the buffer weight and spring tension. Fire a 9mm PCC with a standard 3-ounce carbine buffer, and you’ll experience violent cycling, excessive felt recoil, and accelerated wear on your lower receiver’s buffer tube threads.

PCC buffers typically range from 5 to 8.5 ounces—significantly heavier than anything used in gas-operated rifles. The extra mass is necessary to slow the bolt carrier’s rearward travel and absorb the blowback energy that would otherwise transfer directly to the shooter.

For 9mm PCCs, most builders start with a 5 to 6-ounce buffer. This weight handles common 115-grain and 124-grain ammunition reliably while keeping recoil manageable. I’ve run a 5.4-ounce buffer in my competition PCC for three years and approximately 15,000 rounds without issues.

Larger pistol calibers require proportionally heavier buffers. A .40 S&W PCC typically needs 6.5 to 7.5 ounces, while .45 ACP builds often require 7 to 8.5 ounces to cycle smoothly. The increased case volume and powder charge of these cartridges generates more blowback force that demands additional buffer mass.

Several manufacturers offer PCC-specific buffer kits. Spinta Precision, Kaw Valley Precision, and Blitzkrieg Components all produce dedicated PCC buffers in various weights. Some systems, like the Kaw Valley Precision adjustable buffer, let you add or remove internal weights to fine-tune performance for your specific ammunition and bolt carrier combination.

One critical note: PCC buffers work with standard carbine buffer tubes and springs, though many builders upgrade to extra-power springs (often rated at 10-13 pounds vs. standard 9-pound springs) for additional cycling control. The heavier spring combined with the heavy buffer creates a system that tames blowback operation effectively.

The A5 Buffer System: A Better Mousetrap?

The A5 buffer system represents one of the most significant innovations in AR-15 buffer technology over the past two decades, though it often flies under the radar for builders focused on the latest handguards or triggers.

Originally developed by VLTOR at the request of the U.S. Marine Corps, the A5 was designed to replicate the smooth recoil impulse of a rifle-length buffer system while maintaining the compact dimensions of a carbine setup.

Here’s what sets the A5 apart: it uses a buffer that’s roughly 0.75 inches longer than a standard carbine buffer but still shorter than a full rifle buffer. This intermediate length requires a proprietary A5 buffer tube that’s also slightly longer than mil-spec carbine tubes. The system pairs this extended buffer with a rifle-length spring, creating what many shooters describe as the smoothest-cycling AR-15 buffer assembly available.

I’ve run A5 systems on several of my personal rifles, and the difference in felt recoil is immediately noticeable. The longer stroke allows the bolt carrier group to decelerate more gradually, which translates to reduced perceived recoil and less violent cycling.

This isn’t just subjective feel—the extended dwell time means the BCG isn’t slamming into the buffer as abruptly, which can extend the service life of internal components and reduce the notorious “AR sproing” noise that standard buffer springs often produce.

The A5 system requires three specific components working together: an A5-length buffer tube, an A5-sized buffer (available in multiple weights), and a rifle-length buffer spring. You cannot mix and match these with standard carbine parts. VLTOR pioneered the system, but several manufacturers now produce A5-compatible components.

BCM offers excellent A5 buffer kits with their choice of buffer weights. Forward Controls Design makes premium A5 buffer tubes with features like 9-position adjustments. Sons of Liberty Gun Works produces their Loyal 9 A5 tube, which has developed a strong following among serious shooters.

A5 buffers are available in the same weight progression as standard carbine buffers—from standard weight (approximately 3.8 oz) through H1, H2, and H3 variants. Some manufacturers even offer specialty weights like 6.08-ounce and 6.83-ounce options for highly specific tuning applications.

When does the A5 system make sense? I recommend it for mid-length gas systems running 14.5-inch to 16-inch barrels, where it truly shines. It’s also an excellent choice for suppressed shooting, as the longer buffer stroke helps manage the increased back pressure without requiring you to immediately jump to an H3 buffer. Competition shooters appreciate the smoother impulse for faster follow-up shots, and anyone building a precision-oriented carbine will benefit from the reduced mechanical noise.

The main drawback is cost—a complete A5 setup typically runs $80-120, compared to $40-60 for a standard carbine buffer kit. You’ll also need to ensure your stock is compatible with the slightly longer A5 tube, though most modern adjustable stocks accommodate it without issue. For builders who want the absolute best-cycling AR-15 and don’t mind the premium, the A5 system delivers performance that’s difficult to match with standard carbine components.

Buffer Weight Selection by Configuration

| Configuration | Gas System | Barrel Length | Recommended Buffer | Notes |

|---|---|---|---|---|

Standard AR-15 | Mid-length | 14.5-18" | Carbine (3 oz) or H1 (3.8 oz) | Most versatile |

Carbine Gas | Carbine | 10.5-16" | H2 (4.6 oz) or H3 (5.4 oz) | Counters overgassing |

Pistol/SBR | Pistol/Carbine | <12" | H2-H3 | Short gas systems need heavier |

Suppressed Shooting | Any | Any | Add 0.8-1.6 oz to baseline | Suppressor increases back pressure |

300 BLK | Pistol | <16" | H2-H3 | Higher muzzle energy |

Fixed Stock Rifle | Rifle | 20" | Rifle buffer (5 oz) | Requires rifle-length tube |

How Gas System Length Affects Buffer Weight Choice

Shorter gas systems generate higher port pressure, driving the BCG rearward more aggressively. This relationship directly determines your buffer weight needs.

Pistol-length gas systems (typical on 10.5-inch barrels) position the gas port just 4 inches from the chamber, creating violent cycling that requires H2 or H3 buffers to manage. Carbine-length systems on 10.5 to 16-inch barrels are inherently overgassed and benefit from H2 or H3 weights to reduce component wear and felt recoil.

Mid-length gas systems (14.5 to 16-inch barrels) occupy the sweet spot with moderate gas pressure. These typically run best with standard carbine or H1 buffers, though specific gas port sizing may push you toward H2 weights.

Rifle-length systems on 20-inch barrels have the gas port positioned roughly 12 inches from the chamber. Chamber pressure drops significantly by this point, producing gentle cycling that works well with lighter rifle-length buffers (5 oz).

The practical implication: shorter gas systems don’t just feel harsher—they accelerate parts wear. A properly buffered carbine-gas system can exceed 20,000 rounds before showing significant wear, while an under-buffered setup may develop carrier key problems or cracked bolt lugs before 10,000 rounds.

Suppressor Considerations: Why Everything Changes

Adding a suppressor increases backpressure that effectively amplifies gas port pressure. Your buffer weight needs to account for this.

The general rule: add 0.8 to 1.6 ounces to your baseline buffer weight when shooting suppressed. If you’re running a carbine buffer (3 oz) unsuppressed, expect to need an H2 (4.6 oz) or H3 (5.4 oz) with a can attached.

Backpressure varies by suppressor design. Low back-pressure cans like the CGS Helios may only require stepping up one buffer weight. Traditional baffled suppressors like the SureFire RC2 or Dead Air Sandman generate more backpressure, often requiring two weight classes higher.

Adjustable gas blocks offer an alternative approach, letting you tune gas flow rather than simply adding buffer mass. Many dedicated suppressor hosts run adjustable gas blocks dialed back, paired with H2 buffers for optimal performance.

Lightweight vs Heavy BCG Interactions: The Balancing Act

Your buffer and BCG weights work together to control cycling rate. Change one, and you’ll need to adjust the other.

Lightweight BCGs (8-9 oz vs. standard 11.5 oz) cycle more violently and typically require increasing buffer weight by one class—carbine to H1, H1 to H2, etc. Without this adjustment, the faster-moving carrier can outrun magazine springs, causing feeding issues.

Heavy BCGs (12-13 oz) slow cycling naturally. Pairing a heavy carrier with an H3 buffer risks short-stroking, especially with standard-pressure ammunition. Drop one buffer weight class to compensate—if you’d normally run H2, try H1 with a heavy BCG.

The main idea here is that the buffer and BCG aren’t separate components—they’re partners in managing cycling rate. When speccing a build, consider them as a complete recoil management system. Get the balance right and your rifle runs smoothly; get it wrong and you’ll troubleshoot reliability problems for months.

Modern Buffer Innovations

The AR-15 buffer system hasn’t exactly been a hotbed of innovation over the decades—until recently. While Eugene Stoner’s basic design of a buffer, spring, and tube has served us well since the 1960s, the past ten years have brought some genuinely clever solutions to long-standing annoyances and performance limitations. These modern systems won’t be necessary for every build, but they address real problems that traditional buffers can’t solve.

Silent Captured Spring Systems

Anyone who’s spent time around AR-15s knows the sound: that metallic “sproing” that reverberates through the buffer tube with every shot. It’s the buffer spring vibrating against the inside of the tube, and while it doesn’t affect function, it’s undeniably annoying—especially when you’re trying to maintain a low acoustic signature or just want a rifle that sounds as refined as it performs.

Silent captured spring systems eliminate this noise entirely by containing the spring and buffer in a single self-contained unit. The JP Enterprises Silent Captured Spring Gen 2 pioneered this concept and remains the gold standard. Instead of a loose spring bouncing around inside the tube, JP’s system uses a captured spring assembly with highly polished components that glide smoothly without metal-on-metal contact. The difference is immediately apparent: the action cycles with a quiet, smooth stroke that feels more like a high-end bolt gun than a traditional AR.

I installed a JP Silent Captured Spring in my 6.5 Grendel precision build, and it transformed the rifle’s feel. The elimination of spring noise was nice, but the real benefit was the smoother recoil impulse. The captured spring design provides more consistent resistance throughout the stroke, which translates to more predictable recoil management and faster sight recovery between shots.

The Armaspec SRS Gen 4 takes a similar approach but with a multi-stage spring design. The system uses progressive spring rates—softer initially to cushion the bolt’s rearward travel, then firmer to return it to battery. Some shooters swear by this setup for reducing felt recoil beyond what traditional buffers can achieve. Armaspec’s system is also generally more affordable than JP’s, making it an attractive option for builders who want captured spring benefits without the premium price tag.

The main consideration with silent captured springs is compatibility. These systems are drop-in replacements for standard carbine buffer assemblies, but they’re typically calibrated for specific applications. JP offers different spring rates for suppressed shooting, lightweight BCGs, and various calibers. You need to select the right configuration for your rifle, and unlike traditional buffers where you can easily swap weights, captured spring systems aren’t as easily tuned once installed.

Hydraulic Dampening: The KynSHOT Difference

If captured springs represent evolutionary refinement, hydraulic buffers are something else entirely. The KynSHOT Precision Carbine Recoil Damper replaces the traditional buffer with a hydraulic mechanism that absorbs the bolt carrier’s impact through fluid resistance rather than spring compression alone.

The theory is sound: hydraulic dampening provides progressive resistance that increases as the BCG’s velocity increases, which should translate to smoother cycling and reduced felt recoil. KynSHOT claims 20-30% recoil reduction compared to standard buffers, and from the testing I’ve done, that’s not marketing hyperbole. The rifle genuinely feels softer-shooting, particularly with rapid strings of fire where the hydraulic system really shines.

The KynSHOT system works with your existing buffer tube and spring—it’s the buffer itself that contains the hydraulic mechanism. This makes it a simpler upgrade path than captured spring systems, though at a similar price point ($100-130). The hydraulic buffer is also available in different weights to match your rifle’s gas system, just like traditional buffers.

One interesting benefit I didn’t expect: the hydraulic system seems to make rifles more forgiving of marginal gas system tuning. A rifle that was on the edge of being undergassed with a standard buffer often cycles more reliably with a KynSHOT, presumably because the hydraulic resistance profile is different from pure spring compression.

The drawback? Long-term durability is still somewhat unknown territory. These systems have been on the market for several years now and seem reliable, but we don’t have the decades of field data that traditional buffers provide. The hydraulic seals are consumable components that will eventually need replacement, though KynSHOT offers rebuild services.

Specialty Springs: The Details Matter

Sometimes the innovation isn’t in replacing the whole system—it’s in refining the spring itself. The Geissele Super 42 braided wire spring represents this philosophy perfectly. Instead of a conventional coiled spring, Geissele uses three independent strands of wire wound together, a design borrowed from the German MG42 machine gun.

This braided design acts as a harmonic damper. The three strands can flex independently, which dramatically reduces spring noise and prevents the spring from developing the “memory” that causes conventional springs to lose tension over time. I’ve been running Super 42 springs in several rifles for years, and they genuinely don’t develop the set that standard springs show after a few thousand rounds. The elimination of spring twang is just a bonus.

Tubbs flat-wire springs take a different approach, using flat wire instead of round wire in the spring construction. This increases the surface area in contact with the buffer tube, which can reduce friction and noise. Some shooters find Tubbs springs a bit stiff for properly-gassed rifles, but for overgassed builds or suppressed shooting, that extra tension can be beneficial.

Sprinco springs offer yet another variation with their proprietary design that reportedly extends spring life and provides more consistent tension. I haven’t personally tested these as extensively as Geissele or Tubbs offerings, but they have a strong reputation among competitive shooters who beat on their rifles hard.

These specialty springs typically work with standard buffers and buffer tubes, making them the most affordable entry point into buffer system upgrades. A Super 42 spring runs about $45-50, compared to $100+ for captured spring systems. For builders who want improved performance without completely rethinking their buffer assembly, a quality spring upgrade delivers real benefits at a reasonable cost.

Ready for your next build?

It’s incredibly easy to get lost in the weeds of an AR-15 build. The best way to make sure you stay on track (and actually build what you want) is to start with a list of all of the components you’ll need for your build, with the buffer tube kit and buttstock mapped out together.

Since these two components must be compatible, it’s important to shop for these at the same time using the same criteria.

Sources

- Thomas Schwenke, M16 and AR-15 – How firearms work! (Animation), February 23, 2019

- Stag Arms Blog, Commercial vs. Mil-Spec Buttstocks

- Strong Side Tactical, Buffer Tube Variations Explained

- The Metal Press, 6061 vs 7075 Aluminum

- Google Patents, Firearm buffer system and buttstock assembly

- 80% Arms, AR-15 Buffer Weights: What The Difference Is, and How to Choose

Reviewed

December 14, 2025 — Added two major sections expanding buffer tube kit content: A5 Buffer System coverage (VLTOR’s rifle-smooth carbine alternative) and Modern Buffer Innovations (silent captured springs, hydraulic dampening, specialty springs).

Sign up for our newsletter

Get discounts from top brands and our latest reviews!