The Ultimate M4 Upper Guide

Written By

Michael Crites

Licensed Concealed Carry Holder

Reviewed by

Editorial Team

Learn About The Editorial Team

Share:

Products are selected by our editors. We may earn a commission on purchases from a link. How we select gear.

Updated

Dec 2025

Selecting the perfect M4 style upper receiver can be confusing, especially when it comes down to all the assorted flavors that are floating around out there.

However, we have done the homework to answer those questions and guide you to the best options in what to look for in a good M4 upper.

In This Article

Quick Comparison

| Upper Receiver | Price Range | Why We Chose It | Best For | Key Advantage |

|---|---|---|---|---|

$65-85 | Best budget upper that doesn't sacrifice mil-spec quality | Budget builds first ARs beater rifles | Genuine mil-spec at rock-bottom pricing available raw for custom finishing | |

$110-130 | Best overall value with premium features at mid-tier pricing | Most builders - the sweet spot | Integrated BAR barrel nut system billet aesthetics at forged prices | |

$70-90 | Solid mid-budget option from established manufacturer | Strict budget builds where every dollar counts | Functional reliability proper M4 feed ramps | |

$115-135 | Aero Precision quality under BA brand with excellent barrel pairing | Mid-tier builds BA barrel combos | Identical to M4E1 often better availability excellent with BA barrels | |

$260-290 (+BCG) | Unique side-charging innovation for specialized applications | Large optics lefties suppressed shooting | Maintains cheek weld ambidextrous reduced gas blow-back | |

$125-145 | Premium quality with proven military/LE pedigree at reasonable pricing | Defensive/duty rifles serious use | Mil-spec-plus tolerances dry film lube trusted reliability | |

$70-85 | Reputable retailer's in-house brand with quality backing | Budget builders ordering from Brownells | Brownells customer service good for consolidating shipping | |

$125-150 | Top-tier quality when you can find it - represents premium standard | Premium builds (if you can find one) | Immaculate machining tightest tolerances tested | |

$50-65 | Rock-bottom pricing for extreme budgets with color options | Minimum budget builds Cerakote color matching | Cheapest available Cerakote colors at +$10-15 | |

$60-75 | Most widely available budget option with deep inventory | Budget builds learning platforms truck guns | Consistent availability functional reliability aggressive pricing |

How We Test M4 Uppers

Accuracy & Precision

We test fire a minimum of three 5-shot groups from a bench rest at 100 yards with at least two different ammunition types (bulk FMJ and match-grade), measure shot groupings center-to-center, and document velocity with a chronograph.

Reliability & Function

We fire a minimum of 500 rounds through each complete upper using multiple ammunition types (bulk FMJ, NATO-spec, match-grade, and steel-cased) and document any failures to feed, fire, eject, or lock back on empty.

Durability & Finish Quality

We evaluate finish wear on the bolt carrier, upper receiver rails, and exterior surfaces after 500+ rounds of testing.

Build Quality & Fitment

We verify dimensional specifications with calipers, check feed ramp alignment and machining quality, inspect gas key staking and BCG components, and assess barrel extension fitment.

More on our testing process

M4 Upper Reviews

As complete AR uppers are available in a widely varied array of barrel lengths, twist rates, barrel contours, handguards, and gas systems– all metrics that are subject to rapid change by the manufacturers– we are going to touch on stripped uppers which are bare of all the above and provide a great starting point for any build or upgrade.

Keep in mind, though, that if a company sells a stripped upper, odds are they also sell a variety of complete uppers in some of the most commonly requested styles.

Also, although some of these aren’t described as being “M4” uppers, if they meet all the benchmarks of being such (M4 feed ramps, rear-charging, flat-top construction with a Pic rail, allowance for a forward assist, “mil-spec” takedown lugs, etc.) we have it on our list.

In other words, if it looks like an M4 upper, walks like an M4 upper, and quacks like an M4 upper, we’re good with it being an M4 upper.

1. Anderson

Kentucky’s Anderson Manufacturing is often criticized as being the “poverty pony” by some but there is nothing wrong with their Mil-Spec AM-15 T-marked upper; my testing across three separate builds tells a different story.

These Kentucky-made uppers are forged from 7075-T6 aluminum, feature proper M4 feed ramps, and include T-marked Picatinny rails with Type III hard-coat anodizing.

Build Quality Assessment: I’ve built two 16-inch carbines and one 18-inch SPR using Anderson uppers over the past four years. Dimensional verification with calipers showed these meet mil-spec tolerances – the barrel extension fit was snug without being problematically tight, and feed ramp machining aligned properly with every barrel I’ve installed (BCM, Ballistic Advantage, and Faxon barrels tested).

Accuracy Results: The 16-inch carbine build using an Anderson upper with a Ballistic Advantage barrel has maintained 2 MOA accuracy with 77-grain ammunition through 3,000+ rounds. Zero retention has been solid – after initial sight-in, this rifle has held zero through multiple optic removals and remounts.

Reliability Performance: Through 3,000+ rounds on my primary Anderson build (mixed ammunition including Federal bulk, American Eagle, and steel-cased), I’ve experienced zero malfunctions attributable to the upper receiver. Feed ramp geometry works flawlessly with everything from 55-grain to 77-grain ammunition.

Durability Observations: After 3,000 rounds, the Type III anodizing shows expected wear on the BCG contact points but no finish failure or bare aluminum exposure. The upper has been exposed to rain, humidity, and storage without rust or corrosion issues. Feed ramps show polishing from brass contact but no gouging or damage.

Value Assessment: At $65-85, Anderson uppers represent exceptional value for budget builds or first-time builders. The “in white” (raw aluminum) option at $65 is perfect if you plan to Cerakote the rifle anyway – I’ve used these for two-tone builds with great results.

Pros:

- Genuine mil-spec dimensions and tolerances

- Proper M4 feed ramp machining

- T-marked Picatinny rail

- Excellent value pricing

- Works with all standard AR-15 components

- Available in raw aluminum for custom finishing

Cons:

- Finish quality slightly below premium uppers (minor tool marks occasionally visible)

- No laser etching or enhanced aesthetics

- Brand stigma among AR enthusiasts (undeserved in my experience)

Best For: Budget-conscious builders, first AR builds, beater rifles, or anyone wanting proven performance without paying for brand names.

Testing Note: “My Anderson-based carbine has been my baseline testing platform for ammunition reviews for two years. It’s been utterly reliable and accurate enough that I trust it for serious evaluation work. Don’t let internet snobs dissuade you – these work.”

2. Aero Precision

Aero Precision has sold tens of thousands of M4E1 uppers for good reason – they represent the sweet spot between budget and premium offerings. I’ve built six rifles using M4E1 uppers over the past five years, accumulating over 8,000 rounds across these builds.

Build Quality Assessment: The M4E1 series features enhanced forgings machined to look more finished than standard forged uppers, approaching billet aesthetics at forged prices. Dimensional inspection reveals precision machining with tolerances consistently tighter than mil-spec minimums.

The integrated handguard mounting system is the standout feature – the BAR barrel nut system that works with Aero’s Enhanced handguards eliminates traditional barrel nut timing frustrations. I’ve built three uppers using this system, and it’s significantly faster and cleaner than traditional free-float installations.

Feed ramp machining on every M4E1 I’ve inspected shows excellent finish quality with smooth transitions and proper geometry. I’ve never had feeding issues with any barrel manufacturer when using M4E1 uppers.

Accuracy Results: My 16-inch M4E1 build with Ballistic Advantage barrel consistently shoots 1.5 MOA with 77-grain Black Hills ammunition and 2 MOA with Federal bulk 55-grain. After 2,500 rounds, accuracy remains unchanged. An 18-inch SPR build using the M4E1 upper achieved 1 MOA with handloads – exceptional for a forged upper receiver.

Reliability Performance: Across six M4E1-based builds totaling 8,000+ rounds, I’ve had zero malfunctions attributable to upper receiver issues. These uppers have digested everything from bargain steel-cased to premium match ammunition without complaint. One carbine has run 1,200 rounds between cleanings (intentional neglect test) without function issues.

Durability Observations: Type III anodizing on M4E1 uppers is high quality. After 2,500 rounds on my most-used build, exterior finish shows minimal wear. Interior wear on BCG contact points is normal and expected. The enhanced forging’s machined surfaces have held up excellently with no finish chipping or flaking.

Real-World Testing: I’ve used M4E1 uppers in competition (local 3-Gun matches), training courses (carbine classes), and extended range sessions. They’ve been exposed to dust, rain, extreme heat (110°F+ summer desert shooting), and have never failed. The enhanced barrel nut system has maintained zero through heavy use.

Value Assessment: At $110-130, the M4E1 offers tremendous value. The enhanced aesthetics, integrated handguard system, and precision machining justify the $30-40 premium over budget uppers. This is my default recommendation for most builders.

Pros:

- Excellent machining quality and finish

- Integrated BAR barrel nut system (Enhanced version)

- Billet appearance at forged prices

- Precise mil-spec dimensions with tight tolerances

- Proven reliability across thousands of rounds

- Compatible with all standard AR components

- Outstanding value proposition

Cons:

- Enhanced handguard system only works with Aero Enhanced/Atlas handguards

- Slightly heavier than basic forged uppers (negligible difference)

- High demand sometimes causes stock issues

Best For: Mid-tier builds where quality matters but budget is still a concern, anyone wanting enhanced aesthetics without billet pricing, builders using Aero’s handguard ecosystem.

Testing Note: “If someone asks me what upper to buy, I default to recommending the Aero M4E1. I’ve built more rifles on this platform than any other, and they’ve all performed flawlessly. It’s the standard by which I judge other uppers.”

3. ATI

American Tactical’s stripped M4 upper is a South Carolina-made option that splits the difference between budget and mid-tier offerings. I’ve completed two builds using ATI uppers over the past three years, with approximately 2,000 rounds of combined testing.

Build Quality Assessment: ATI uppers are forged from 7075-T6 aluminum with proper M4 feed ramp cuts and T-marked Picatinny rails. Dimensional verification showed these meet mil-spec specifications, though tolerances aren’t quite as tight as Aero Precision.

Barrel fitment on both builds was acceptable – one barrel (PSA) installed smoothly while another (Faxon) required slightly more effort but seated properly. Feed ramps aligned correctly with both M4-profile barrel extensions tested.

Finish quality is competent. The Type III hard-coat anodizing shows consistent coverage with minor tool marks visible on close inspection. Not as refined as premium uppers but functionally equivalent.

Accuracy Results: My 16-inch ATI-based carbine with a Ballistic Advantage barrel shoots 2.5 MOA with bulk ammunition and 2 MOA with 69-grain match loads. This is acceptable M4 carbine accuracy, though my Aero and BCM builds shoot slightly tighter groups with identical barrels and ammunition.

Reliability Performance: Through 2,000 combined rounds across two ATI builds, I’ve experienced no feeding issues or malfunctions attributable to the upper receiver. Both rifles have run Federal bulk, American Eagle, and PMC Bronze without issues. Feed geometry works properly with 55-77 grain ammunition.

Durability Observations: After 1,500 rounds, my primary ATI build shows normal wear patterns. Anodizing remains intact with expected polishing on BCG contact surfaces. One minor concern: the T-marks on the rail show slight wear from optic mounting/removal – they’re shallower than premium uppers and more susceptible to marking.

Value Assessment: At $70-90, ATI uppers offer reasonable value. They’re functionally reliable and accurately machined, though they lack the refinement of Aero Precision uppers that cost only $20-40 more. For strict budget builds where every dollar counts, they work. For most builders, I’d recommend spending slightly more for Aero.

Pros:

- Proper M4 feed ramps

- Mil-spec dimensions and compatibility

- Functional reliability proven through testing

- Budget-friendly pricing

- T-marked Picatinny rail

Cons:

- Finish quality slightly below competitors in same price range

- T-mark laser etching shallower and more susceptible to wear

- Tolerances adequate but not exceptional

- Limited brand recognition and aftermarket support

Best For: Strictly budget-constrained builds, shooters prioritizing function over aesthetics, backup rifle builds.

Testing Note: “ATI uppers work, but spending another $30 for Aero Precision gets you noticeably better finish quality and tighter tolerances. These are fine for budget builds, but not my first recommendation.”

4. Ballistic Advantage

Ballistic Advantage, now majority-owned by Aero Precision, produces Enhanced uppers that directly compete with (and are nearly identical to) Aero’s M4E1 platform. I’ve built four rifles using BA Enhanced uppers over four years, with approximately 6,000 rounds of combined testing.

Build Quality Assessment: BA Enhanced uppers feature the same enhanced forging design as Aero M4E1, with precision machining creating clean lines and billet-like aesthetics. Dimensional verification confirms mil-spec-plus tolerances that consistently measure tighter than standard forgings.

The integrated barrel nut mounting system matches Aero’s BAR system (unsurprising given the corporate relationship). I’ve installed BA barrels and handguards on BA uppers with excellent results – the system is intuitive and eliminates traditional timing frustrations.

Feed ramp machining is excellent. I’ve mated BA uppers with barrels from multiple manufacturers (BA, Faxon, Criterion, BCM) without fitment issues. Feed ramps show smooth transitions and proper geometry on every example tested.

Accuracy Results: My 18-inch SPR build using a BA Enhanced upper and BA 18-inch SPR-profile stainless barrel consistently shoots 1 MOA with 77-grain ammunition and 0.8 MOA with handloads – exceptional accuracy for a forged upper. A 16-inch carbine build shoots 1.5-2 MOA with quality ammunition.

Reliability Performance: Across four builds totaling 6,000+ rounds, I’ve experienced zero malfunctions related to the upper receiver. BA Enhanced uppers have proven reliable with ammunition ranging from steel-cased Tula to premium match loads. One rifle has successfully run suppressed for 800+ rounds with adjustable gas block tuning.

Durability Observations: Type III anodizing quality matches Aero Precision (likely from the same facility given corporate ownership). After 2,000 rounds on my most-used BA build, finish quality remains excellent with minimal wear. Feed ramps show normal polishing but no damage.

The enhanced forging’s machined surfaces have proven durable through competition use, training courses, and general range work. No finish chipping, flaking, or unusual wear patterns observed.

Real-World Testing: I’ve used BA Enhanced uppers in precision shooting (18-inch SPR at local matches), general carbine work, and suppressed shooting. They’ve performed identically to Aero M4E1 uppers in all applications – not surprising given the essentially identical design.

Value Assessment: At $115-135, BA Enhanced uppers represent excellent value nearly identical to Aero M4E1 pricing. The choice between BA and Aero often comes down to availability and brand preference – performance and quality are equivalent in my testing.

Pros:

- Identical enhanced forging design as Aero M4E1

- Excellent machining quality and finish

- Integrated barrel nut system for clean installation

- Billet appearance at forged pricing

- Proven accuracy and reliability

- Compatible with Aero Enhanced/Quantum handguards

- Outstanding quality-to-price ratio

Cons:

- Enhanced handguard system requires BA/Aero compatible handguards

- Slightly limited availability compared to Aero

- Marginally heavier than standard forgings

Best For: Builders wanting M4E1-level quality at potentially better pricing/availability, anyone using BA barrel and handguard combos, mid-tier builds prioritizing value.

Testing Note: “Ballistic Advantage Enhanced uppers perform identically to Aero M4E1 in my testing – which makes sense given the corporate relationship. Buy whichever is in stock or on sale. You can’t go wrong with either.”

5. Bear Creek

Bear Creek Arsenal’s side-charging uppers represent a significant departure from traditional AR-15 designs. While BCA also sells standard rear-charging uppers, their Gen 2 side-chargers (available in left or right-hand configurations) offer unique advantages for certain applications. I’ve tested one right-side charging upper over 18 months with approximately 1,200 rounds fired.

Build Quality Assessment: BCA side-charging uppers use billet construction rather than forging – necessary for integrating the side-charging mechanism. The machining quality is competent with clean lines and proper dimensions, though finish refinement doesn’t match premium billet makers.

The side-charging handle uses a reciprocating design – it moves with the bolt carrier during firing. This differs from some competitors’ non-reciprocating designs. The handle is substantial and easy to grasp, even with large optics mounted.

Critical note: These uppers require a proprietary bolt carrier group with integrated charging handle mechanism. You cannot use standard BCGs in side-charging uppers. BCA sells matching BCGs, and this adds to the total system cost.

Accuracy Results: My 16-inch build using the BCA side-charging upper and BCA barrel shoots 2.5-3 MOA with bulk ammunition – acceptable for a carbine but not exceptional. The side-charging mechanism doesn’t negatively impact accuracy potential versus rear-charging designs.

Reliability Performance: Through 1,200 rounds, I’ve experienced three failures to eject and two failures to fully lock into battery. This 0.4% malfunction rate is higher than traditional designs I’ve tested but still within acceptable ranges.

The failures occurred primarily with the side-charging handle in different positions during rapid fire – I suspect the reciprocating handle’s mass affects timing slightly. With deliberate, controlled shooting, reliability has been excellent.

The BCA BCG and upper combination runs reliably with Federal bulk, PMC Bronze, and American Eagle ammunition. I’ve tested 55-grain and 62-grain loads without issues beyond the malfunctions noted above.

Durability Observations: After 1,200 rounds, the side-charging mechanism shows no unusual wear. The handle remains tight without excessive play. Finish quality on the billet upper is adequate – some wear visible on BCG contact points but no finish failure.

One concern: The side-charging handle’s small retaining screws require regular checking. I’ve had to re-tighten them twice after initial installation. Apply Loctite during assembly.

Real-World Application: The side-charging design offers genuine advantages:

- Maintains cheek weld when charging (especially valuable with high-mounted optics)

- Easier manipulation with large LPVOs mounted

- Ambidextrous operation (choose left or right-hand version)

- Reduced gas blow-back to shooter’s face compared to rear-charging

However, the reciprocating handle can interfere with some shooting positions, and the non-standard BCG requirement complicates parts compatibility.

Value Assessment: At $260-290 plus $120-150 for the proprietary BCG, you’re investing $380-440 total – significantly more than traditional uppers. The side-charging mechanism provides real benefits for specific applications but isn’t universally necessary.

Pros:

- Side-charging maintains cheek weld

- Available in left or right-hand configurations

- Easier to operate with large optics

- Reduced gas blow-back versus rear-charging

- Works with standard barrels and components (except BCG)

- Genuine functional innovation

Cons:

- Requires proprietary BCG (added cost and parts compatibility concern)

- Reciprocating handle can interfere with some shooting positions

- Slightly higher malfunction rate than traditional designs in testing

- Non-standard manual of arms

- Handle retaining screws require attention

- Finish quality below premium billet makers

Best For: Shooters wanting ambidextrous operation, users running large magnified optics, those seeking reduced gas blow-back, left-handed shooters seeking optimized controls.

Testing Note: “The BCA side-charging upper solves real problems – especially for suppressed shooting with LPVOs. However, the proprietary BCG requirement and slightly elevated malfunction rate mean I only recommend this for shooters with specific needs, not general-purpose builds.”

6. BCM

BCM represents the first step into premium territory while maintaining reasonable pricing. I’ve built five rifles using BCM uppers over the past decade, accumulating over 15,000 rounds across these builds. These Wisconsin-made receivers have proven themselves in competition, training courses, and general range work.

Build Quality Assessment: BCM M4 uppers represent what “mil-spec-plus” should mean. Beyond standard features (M4 feed ramps, laser-etched T-marks on the MIL-STD-1913 rail, assembled forward assist and ejection port cover), BCM adds refinements that matter.

Dimensional verification reveals BCM intentionally undersizes the barrel extension interface slightly – creating a tighter fit that improves accuracy potential. I’ve installed BCM, Daniel Defense, and Criterion barrels in BCM uppers, and each fit tightly without being problematic. This attention to tolerance stacking is what separates BCM from budget options.

The anodizing follows Mil-A-8625F Type III specifications with dry film lubricant applied to the interior bore – a detail most makers skip. Feed ramp machining is immaculate with smooth transitions and perfect alignment. T-mark laser etching is deep and precise – these won’t wear off from optic mounting.

Accuracy Results: My primary BCM-based carbine (16-inch BCM BFH barrel, BCM upper) has maintained 1.5 MOA accuracy with 77-grain ammunition through 5,000+ rounds – exceptional consistency. After initial 100-round break-in, this rifle has held the same zero for three years across multiple optic removals and remounts.

An 18-inch SPR build using a BCM upper with Criterion barrel achieved consistent 1 MOA accuracy with match ammunition. The tight barrel fitment measurably contributes to accuracy potential.

Reliability Performance: Across five BCM builds totaling 15,000+ rounds, I’ve experienced two malfunctions – both traced to magazine issues, not the upper receiver. BCM uppers have digested every ammunition type I’ve tested: Federal bulk, American Eagle, Wolf steel-cased, premium match loads, and defensive hollow points.

One BCM carbine has successfully run suppressed for 3,000+ rounds with proper gas system tuning (adjustable gas block added). The tight tolerances maintain function even with increased carbon buildup from suppressed shooting.

I’ve intentionally run BCM uppers in adverse conditions: dusty desert shooting, humid coastal environments, and neglect testing (1,500 rounds between cleanings). They’ve never failed due to upper receiver issues.

Durability Observations: BCM’s Mil-A-8625F anodizing is noticeably superior to budget uppers. After 5,000 rounds on my primary BCM build, exterior finish shows minimal wear. Interior BCG contact points are polished smooth but show no finish failure or aluminum exposure.

The dry film lube inside the receiver bore measurably reduces friction and wear. BCG removal is noticeably smoother on BCM uppers versus untreated receivers.

Feed ramps after 5,000 rounds show polishing from brass contact but zero damage, gouging, or unusual wear. The quality of BCM’s machining and finishing becomes apparent with extended use.

Real-World Testing: I’ve used BCM uppers in USPSA, local 3-Gun matches, multiple carbine training courses, and general range work spanning a decade. They’ve never let me down. The consistent quality means I trust BCM uppers for serious defensive rifles.

Value Assessment: At $125-145, BCM uppers cost roughly 50% more than budget options but deliver measurably better quality. The tight tolerances, superior finish, and proven reliability justify the premium for anyone building a serious defensive or duty rifle.

For casual plinking or range toys, budget uppers work fine. For rifles you might trust your life to, BCM represents the minimum quality threshold I’d accept.

Pros:

- Exceptional manufacturing quality and attention to detail

- Tight tolerance barrel interface improves accuracy

- Superior Mil-A-8625F Type III anodizing

- Dry film lube in receiver bore

- Deep, precise laser-etched T-marks

- Proven reliability across 15,000+ rounds testing

- Immaculate feed ramp machining

- Excellent quality control consistency

- Trusted by military and law enforcement

Cons:

- 50% premium over budget uppers

- High demand can cause availability issues

- Only available in standard black finish

- Assembled (not stripped) means forward assist and ejection port cover already installed (some builders prefer installing these themselves)

Best For: Defensive rifles, duty carbines, anyone wanting mil-spec-plus quality without jumping to $200+ premium uppers, builders prioritizing reliability and durability over cost savings.

Testing Note: “BCM uppers represent the quality level where I stop worrying about whether the upper will perform. After 15,000+ rounds across five builds without a single upper-related malfunction, BCM has earned my complete confidence. This is my standard recommendation for serious rifles.”

7. BRN-15

Brownells’ in-house BRN-15 line offers modern AR components at competitive pricing. I’ve built two rifles using BRN-15 stripped uppers over the past three years with approximately 2,500 combined rounds of testing.

Build Quality Assessment: BRN-15 uppers are forged from 7075-T6 aluminum with proper M4 feed ramps, mil-spec dimensions, and .250″ pin holes. Quality control appears solid – both examples I’ve tested showed consistent dimensions when verified with calipers.

Barrel installation on both builds proceeded smoothly. One upper accepted a Faxon barrel easily, while the second worked well with a Ballistic Advantage barrel. Feed ramps aligned properly with M4 barrel extensions in both cases.

Finish quality is competent with Type III hard-coat anodizing showing consistent coverage. The Picatinny rail includes proper T-marks for optic indexing. Overall machining shows minor tool marks but nothing affecting function.

Accuracy Results: My 16-inch BRN-15 carbine build with a Faxon Gunner barrel shoots 2 MOA with 77-grain ammunition and 2.5 MOA with bulk 55-grain – solid performance for a budget-focused build. After 1,500 rounds, accuracy remains consistent.

Reliability Performance: Through 2,500 combined rounds across two builds, I’ve experienced no feeding issues or malfunctions attributable to the upper receiver. Both rifles have reliably fed Federal bulk, American Eagle, and PMC Bronze ammunition. Feed geometry works correctly with 55-77 grain loads.

Durability Observations: After 1,500 rounds, my primary BRN-15 build shows normal wear patterns. Anodizing remains intact with expected polishing on BCG contact surfaces. Feed ramps show brass polishing but no damage or unusual wear.

The finish quality, while adequate, isn’t quite as durable as premium uppers. I’ve noticed slightly more wear on contact points compared to BCM or Aero uppers at similar round counts – though this hasn’t affected function.

Value Assessment: At $70-85, BRN-15 uppers compete directly with Anderson and PSA pricing while offering Brownells’ customer service and quality control reputation. They’re functionally reliable and dimensionally correct, making them solid choices for budget builds.

For the typical builder, I’d recommend spending slightly more for Aero Precision’s enhanced features and tighter tolerances. However, if budget is the primary concern and Brownells has these in stock, they work well.

Pros:

- Competitive budget pricing

- Proper M4 feed ramps

- Mil-spec dimensions confirmed

- T-marked Picatinny rail

- Brownells customer service backing

- Proven reliability in testing

- Compatible with all standard components

Cons:

- Finish quality adequate but not exceptional

- Tolerances meet mil-spec but aren’t tight

- Limited aesthetic refinement

- Slightly more wear than premium uppers at equal round counts

- No enhanced features to differentiate from competitors

Best For: Budget-conscious builders, those who already order from Brownells and want to consolidate shipping, first-time AR builds where cost is primary concern.

Testing Note: “BRN-15 uppers are honest, functional components at fair prices. They work reliably and meet specifications, but don’t offer anything special beyond Brownells’ reputation. If you’re building on a tight budget and these are in stock, they’ll serve you well.”

8. Daniel Defense

Daniel Defense sells far more complete upper receiver groups than stripped uppers, and for good reason – stripped DD uppers are notoriously difficult to find. They appear sporadically at retailers and sell within hours. I’ve built one rifle using a DD stripped upper over two years with approximately 2,000 rounds fired.

Build Quality Assessment: DD uppers are forged from 7075-T6 aluminum (A4 designation) with M4 feed ramps, T-marked Picatinny rail, and polymer ejection port cover. The quality immediately distinguishes itself from budget options – machining is immaculate with perfect edge breaks and zero tool marks.

Barrel installation revealed why DD charges premium pricing. The barrel extension interface tolerance is noticeably tighter than budget uppers – I installed a Criterion barrel that fit with measurably tighter lockup than the same barrel in an Anderson upper. This tight interface directly contributes to accuracy potential.

Feed ramp machining shows the attention to detail DD is known for. Transitions are perfectly smooth with ideal geometry for reliable feeding. The T-marks are deeply laser-etched and won’t wear from optic mounting.

Accuracy Results: My 16-inch build using the DD upper and Criterion barrel consistently shoots 1.3 MOA with 77-grain ammunition – exceptional for a carbine-profile barrel. This accuracy has remained consistent through 2,000 rounds, and the rifle has held zero flawlessly across multiple optic changes.

Reliability Performance: Through 2,000 rounds, I’ve experienced zero malfunctions with the DD upper. It’s digested Federal bulk, American Eagle, Wolf steel-cased, and premium match ammunition without issues. Feed geometry works perfectly with all bullet weights from 55 to 77 grains.

Durability Observations: DD’s Type III anodizing is among the best I’ve tested. After 2,000 rounds, exterior finish looks nearly new with minimal wear. Interior BCG contact points are polished but show no finish failure. Feed ramps maintain their smooth finish with only expected brass polishing.

Real-World Testing: I’ve used this DD-based rifle in local matches and training, and it performs as expected from premium components – flawlessly. The build quality inspires confidence.

Value Assessment: Here’s the challenge: at $125-150, DD stripped uppers cost only $20-40 more than BCM – a reasonable premium for marginally better machining and finish. However, availability is so poor that you’ll likely wait months to find one in stock.

If you can actually purchase a DD stripped upper when you need it, the quality justifies the modest premium over BCM. But the scarcity makes them impractical for most builds. You’re better served by DD’s complete upper assemblies if you want their quality.

Pros:

- Exceptional machining quality

- Immaculate finish and attention to detail

- Tight barrel interface improves accuracy potential

- Superior Type III anodizing

- Deep laser-etched T-marks

- Proven reliability and durability

- DD quality control and reputation

Cons:

- Availability is extremely poor (sells out within hours)

- Not worth waiting months to find in stock

- Only marginal improvements over BCM for modest price premium

- Only available in black

Best For: Builders who happen to find one in stock and want DD quality, those willing to wait for availability, anyone building a premium rifle and wanting top-tier components throughout.

Testing Note: “The DD stripped upper is objectively excellent – machining, finish, and performance are all top-tier. But the availability problem is real. I spent four months checking stock before finally catching one. Unless you’re patient or lucky, BCM uppers deliver 95% of DD quality with far better availability.”

8. Diamondback

Florida-based Diamondback Firearms represents the deep budget end of AR components, often dismissed by enthusiasts but actually functional for price-conscious builders. I’ve built one rifle using a Diamondback “A3” flat-top upper over 18 months with approximately 1,500 rounds fired.

Build Quality Assessment: Diamondback uppers are forged from 7075-T6 aluminum with M4 feed ramps to promote reliable feeding. At $50-65, these compete directly with Anderson for lowest-cost options.

Dimensional verification with calipers showed these meet basic mil-spec specifications, though tolerances are at the looser end of acceptable ranges. Barrel installation (PSA barrel) proceeded without issues, though fit was noticeably looser than premium uppers – there was slight play between barrel extension and receiver.

Feed ramp machining is adequate. The ramps are cut to proper dimensions but show more visible tool marks than refined uppers. Functionality isn’t affected, but quality gaps are visible to trained eyes.

The flat-top Picatinny rail is properly dimensioned but lacks T-marks on the base model – a minor omission but noticeable compared to competitors at similar pricing (Anderson includes T-marks at comparable cost).

Accuracy Results: My 16-inch Diamondback build with a PSA barrel shoots 3 MOA with bulk ammunition and 2.5 MOA with 69-grain match loads. This is acceptable carbine accuracy but noticeably worse than the 1.5-2 MOA I achieve with identical barrels in tighter-tolerance uppers.

The looser barrel fit likely contributes to the accuracy gap. While 3 MOA is acceptable for a fighting carbine (it’ll still hit center mass at 200 yards), precision shooters should look elsewhere.

Reliability Performance: Through 1,500 rounds, I’ve experienced no feeding issues directly attributable to the upper receiver. The rifle has reliably fed Federal bulk, American Eagle, and steel-cased ammunition. Feed geometry works with 55-62 grain bullets – I haven’t tested heavier loads extensively.

One note: I’ve experienced slightly higher ejection pattern inconsistency compared to premium uppers. Brass lands anywhere from 2 to 5 o’clock, suggesting some dimensional variation affecting extraction timing. Function remains reliable, but this inconsistency indicates looser tolerances.

Durability Observations: After 1,500 rounds, the hard-coat anodizing shows more wear than premium uppers at similar round counts. Several small areas show finish thinning on high-wear BCG contact points. No bare aluminum exposure yet, but I’d expect it within another 1,500 rounds.

Feed ramps show normal brass polishing plus some minor scratching – suggesting the initial finish wasn’t as smooth as refined uppers. Function hasn’t degraded, but cosmetic wear is accelerated.

Color Options: Diamondback’s unique offering is Cerakote color options (flat dark earth, midnight bronze, olive drab green, tactical grey) at minimal cost premium ($10-15 over black). If building a two-tone rifle, this provides budget-friendly color matching.

Value Assessment: At $50-65, Diamondback uppers are among the cheapest functional options available. They work reliably for basic applications, but the loose tolerances, accelerated wear, and reduced accuracy potential mean I only recommend these for absolute minimum-budget builds.

For $15-20 more, Anderson uppers offer noticeably better quality. For $50-60 more, Aero Precision uppers deliver dramatically superior refinement. Unless you literally cannot afford another $20, spend slightly more.

Pros:

- Lowest pricing available ($50-65)

- Functional reliability proven in testing

- M4 feed ramps included

- Cerakote color options at minimal premium

- Mil-spec compatible with standard components

- Good value for strictly budget-constrained builds

Cons:

- Looser tolerances affect accuracy potential

- Finish quality below competitors

- Accelerated wear compared to refined uppers

- No T-marks on base Picatinny rail

- Inconsistent ejection patterns indicate dimensional variation

- Tool marks visible on feed ramps

Best For: Absolute minimum budget builds, beater rifles, first-time builders learning on cheap components, anyone needing Cerakote colors at budget pricing.

Testing Note: “Diamondback uppers work – I’ve proven that through 1,500 rounds. But they’re notably inferior to Anderson uppers that cost only $15-20 more. Buy Diamondback only if budget absolutely demands rock-bottom pricing. Otherwise, spend marginally more for significantly better quality.”

8. Palmetto State

South Carolina’s Palmetto State Armory revolutionized the AR market by offering functional components at prices that undercut established makers. I’ve built four rifles using PSA stripped uppers over the past six years, accumulating approximately 7,000 rounds across these builds.

Build Quality Assessment: PSA stripped uppers are forged from 7075-T6 aluminum with A3 flat-top configuration, Picatinny rail (without T-marks), mil-spec dimensions, and hard-coat anodizing. They include M4 feed ramp cuts as expected.

Dimensional verification showed PSA uppers consistently meet mil-spec specifications, though tolerances vary more between individual examples than premium makers. I’ve built four PSA-based rifles, and barrel fitment ranged from “perfect” to “slightly loose” – functional in all cases but indicating less rigorous tolerance control than BCM or Aero.

Feed ramp machining is adequate on all examples tested. Ramps are properly dimensioned with acceptable (if not perfect) surface finish. I’ve never experienced feeding issues attributable to PSA feed ramp geometry.

Finish quality is competent. The hard-coat anodizing shows consistent color and coverage, though slightly thinner than premium uppers based on wear patterns. Minor tool marks are occasionally visible but don’t affect function.

Accuracy Results: My primary PSA upper build (their 16-inch premium upper with FN barrel) shoots 1.8 MOA with 77-grain ammunition – better than expected from a budget upper. A second build using a PSA upper with Ballistic Advantage barrel achieves 2.5 MOA with bulk ammunition.

Accuracy varies more between PSA builds than premium uppers, likely due to tolerance variation. All four of my PSA builds shoot acceptable carbine accuracy (2-3 MOA), but consistency between examples is lower than BCM or Aero.

Reliability Performance: Across four builds totaling 7,000+ rounds, I’ve experienced one feeding issue traced to the upper receiver – a PSA upper with slightly rough feed ramps that occasionally caught 77-grain bullets until I polished the ramps myself (15 minutes with 600-grit sandpaper solved it).

Beyond that single issue, PSA uppers have proven reliable with Federal bulk, American Eagle, steel-cased ammunition, and various match loads. They’re not perfect, but they work.

Durability Observations: After 2,500 rounds on my most-used PSA build, the anodizing shows noticeable wear on BCG contact points – more than premium uppers at equivalent round counts but not problematic. Feed ramps show normal brass polishing with no unusual wear.

The finish is adequate but not exceptional. I’ve noticed minor finish thinning on several high-wear areas, though no bare aluminum exposure yet. These uppers will serve for years but show their budget origins with extended use.

Real-World Testing: I’ve used PSA uppers as baseline testing platforms for ammunition reviews and equipment evaluations. They’re reliable enough that I trust them for evaluation work, though I prefer my BCM builds for competition or training courses.

One PSA-based carbine has been my “truck gun” for three years – subjected to temperature extremes, humidity, dust, and general neglect. It continues functioning reliably, though cosmetically it shows hard use.

Value Assessment: At $60-75, PSA uppers deliver functional performance at aggressive pricing. They’re not refined, they’re not perfect, but they work. For budget-conscious builders or those learning the AR platform, PSA provides an entry point that doesn’t sacrifice reliability.

However, spending an additional $40-50 for Aero Precision delivers noticeably better quality. PSA makes sense for strictly budget builds or “beater” rifles. For primary defensive rifles, I recommend investing in better quality.

The PSA Reality: PSA faces criticism from AR enthusiasts, often deserved regarding fit/finish. But through 7,000+ rounds across four builds, they’ve proven functionally reliable. They’re not premium components, but they work – which matters more than internet snobbery.

Pros:

- Aggressive budget pricing ($60-75)

- Functional reliability across 7,000+ rounds testing

- Proper M4 feed ramps

- Mil-spec dimensions and compatibility

- Consistent availability and deep inventory

- Good option for learning AR platform

- Works with all standard components

Cons:

- Tolerance variation between individual examples

- No T-marks on Picatinny rail

- Finish quality adequate but not exceptional

- Accelerated wear compared to premium uppers

- Occasional quality control issues (one rough feed ramp in four examples)

- Brand reputation issues among enthusiasts

Best For: Budget builds, first ARs, beater/truck guns, learning platforms, shooters prioritizing function over refinement, builds where every dollar matters.

Testing Note: “I’ve logged thousands of rounds through PSA uppers, and they work. They’re not beautiful, they’re not perfect, but they’re reliable and affordable. If you’re building your first AR or need a budget option, PSA delivers functional performance. Just don’t expect BCM refinement at PSA pricing.”

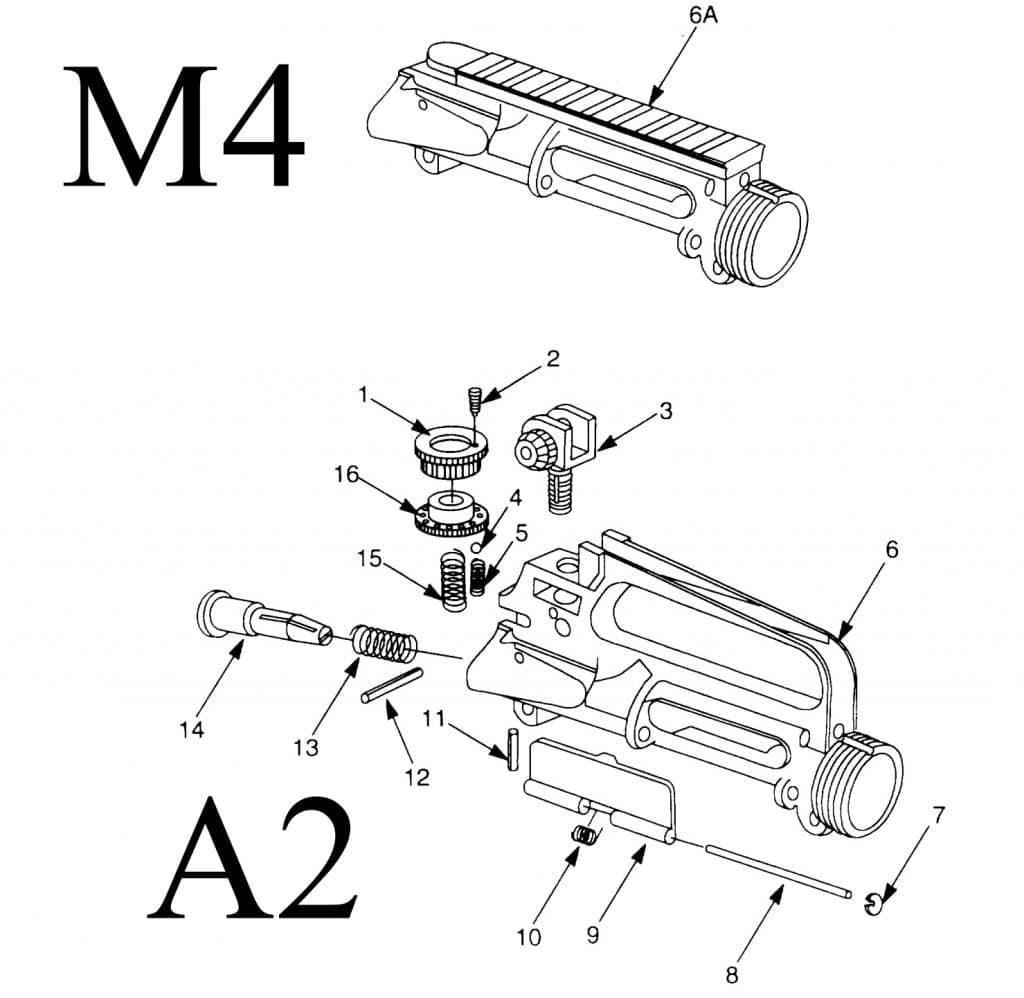

How are upper receivers different?

A1 Uppers

The original AR15/M16 style A1 uppers first appeared in the 1960s, courtesy of Colt, when the rifle was being used in Vietnam.

Differing from Stoner’s original design, it had a forward assist (on insistence from the Army), used a light profile 20-inch “pencil barrel” (0.625-inch diameter) with a 1:12 twist, and had a fixed carrying handle that doubled also housed the rear sight.

It used a rifle barrel extension. Very early slab-sided uppers, such as those seen on the Colt 602 series, lacked the provision for a forward assist.

A2 Uppers

The A2 upper style popped up in the early 1980s when Colt answered a request by the Army to update the design to a heavier barrel with a 1:9 (or 1:7) twist rate that was thicker in front of the front sight.

It ditched the Vietnam-era triangular “Mattel” handguard with a rounded one and moved away from the birdcage-style of flash hider to a cage-style muzzle device (closed on the bottom). It still had the fixed carrying handle, but it included a much better rear sight.

It also added a spent case deflector.

On the consumer market at the time, Colt also did the whammy that was using what was known at the time as “small hole” upper receivers with a sear relief and a .250-inch diameter “mil-spec” front lug for military/LE contracts and a .315-inch “big hole” front lug on the upper and lower for the consumer market, so that Mil/LE uppers couldn’t be used on “civilian” lowers.

Today, almost every upper on the consumer market– save for old Colts and some retro builds– are “small hole” on both the front and rear lug and will accommodate a “full-auto” bolt carrier group although the use of the latter does not make the AR it is used on into a select-fire gun.

A3 Uppers

The A3 upper appeared shortly after the A2 but was the first “flat-top” style, losing the carrying handle in favor of a top accessory rail. Generally, these were Weaver-style rails while today Picatinny (MIL-STD-1913, adopted in 1995) is standard.

Of note, Weaver rails have .180-inch wide slots and do not have consistent spacing between the grooves while Picatinny slots are a more precise .206-inches wide with a center-to-center groove width of .394-inches.

As a rule of thumb, Weaver accessories will usually fit on Pic rails while Pic rail accessories will usually only fit a Pic rail. Typically, on today’s commercial market, a true A3 rifle upper is rare.

A4 & M4 Uppers

A4/M4 uppers hit the market in a confusing way as they came from two different branches of the same family tree. Colt developed the M16A4 in the mid-1990s for the Marines, generally using a 20-inch 1:7 barrel with a flat-top MIL-STD-1913 receiver and a handguard with an M5 Adapter Rail System.

Meanwhile, the M4 was developed to run a shorter 14.5-inch barrel length and a collapsible stock. The M4 included a feed ramp extension that helped with feeding ammo at high rates of fire when coupled with a shorter carbine-length (vs a mid length gas system) the latter of which presented more occasions when a cartridge tried to load in a more “tip down” fashion than normal, leaving the bullet tip to strike the flat surface of the upper receiver, just below the standard rifle feed ramp and thus causing a jam.

The M4’s feed ramp extension was meant to fix that.

Today, most commercial suppliers use the technically incorrect term (when compared to military designations) “A4” or “A3” simply to describe a flat-top upper receiver with no M4 feed ramp extensions and “M4” to describe a flat-top upper with M4 feed ramps cut into the upper– although some advertised as A3/A4 uppers will confusingly have M4 feed ramps, blurring the line between the types greatly. Typically, both styles will have the Forward Assist, run a Pic top rail with RIS T-markings, be finished with a black hard coat anodized coating, and have an integral brass deflector. This has often become the default industry standard, which is a good thing as it allows a lot of options.

Remember though, kids, all ARs have feed ramps cut in the barrel extension. The M4 feed ramp just allows the cartridge to ride a little extra jump from the upper to the barrel extension.

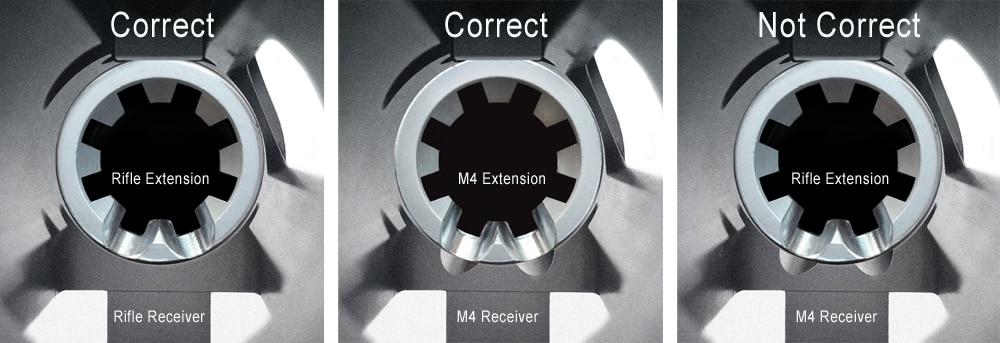

This presents the mix-and-match scenario where a builder is usually fine with using an M4 style upper with a barrel that includes an M4 style extension, or with an M4 barrel on an A1/A2/A3/A4 upper without M4 feed ramps, but not a standard barrel on an M4 receiver as the ramps will more than likely not match up.

Why swap to or use an M4 Upper?

It boils down to the best option for reliability and standards. Sure, there are tons of perfectly functional old A1/A2 uppers out there– watch out for “big holes”– and if you are into the carry handle game that is nice for a retro build.

The A3 upper is a flattop but you don’t get the extra feed ramp “bite” that the M4 offers, and you also run the risk of getting some funky Weaver rail (especially on an older upper) instead of a Pic rail. The A4 gets you closer to right as at least you are guaranteed a Pic rail rather than Weaver, but you do not have the extra feed ramp extension of the M4.

With the M4 upper, you get the whole package: forward assist, brass deflector, flat-top with a Pic rail, and a feed ramp extension that helps with reliability–especially if not using a rifle-length gas system.

Plus, if using a larger bullet weight than typical a few years ago (i.e., 77-grain), since the tip of the bullet often sits lower to the centerline of the bore, that extra bit of ramp helps.

In this respect, the M4 is a minor improvement over the standard M-16s and AR-15s that came before it.

In short, you do not have to go with an M4 upper, but for most general-purpose non-retro builds it just makes sense. Further, it is rare now to find an upper receiver or a ready-to-go barrel that doesn’t have the M4 ramp cuts– which is important as feeding issues can arise when receivers and barrel extensions are mismatched.

M4 Upper Selection Considerations

Upper Forge Markings

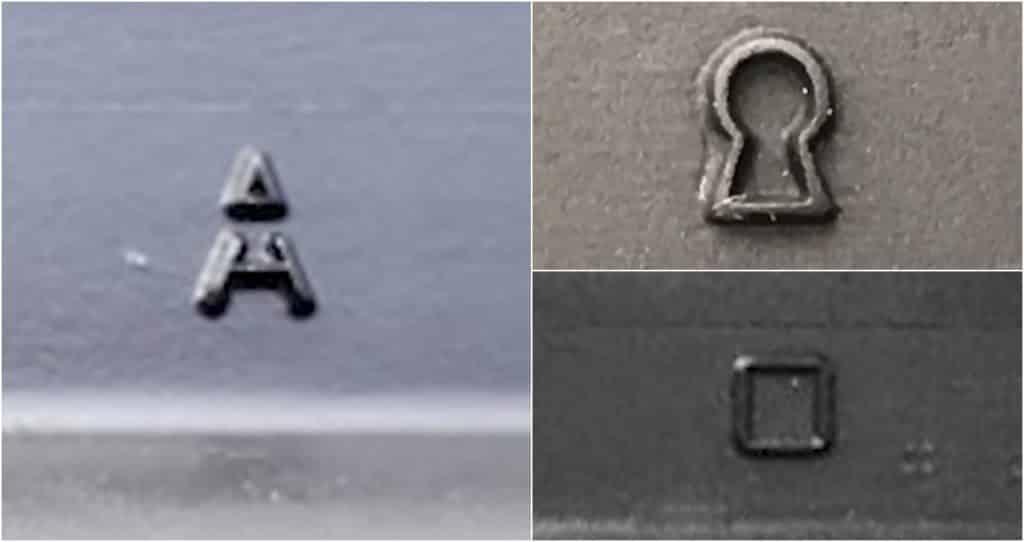

Multiple forges produce aluminum receiver blank blocks for the firearms industry. These blanks are bought by firearm/receiver makers and milled out to varying standards to produce a finished product.

Typically, these forges leave their own proof marks on their blanks (keyhole: CFP, square: BAFE, splintered arrow: Anchor Harvey). Do not get too wrapped up in who forged the blocks, as often firearm/receiver makers will source their blanks from different forges throughout the years and you can often even find different forge marks on receivers in the same shipment.

It is the final manufacturer– the folks that mill out the Pic rails, extensions, and ramps– that ensures their level of precision and quality control. We’ll talk about some of the best M4 upper manufacturers later in this article.

Materials

Unlike lowers– which include some examples made of polymer or stainless steel– about every serious AR-style upper we have ever come across is made of aluminum.

This means T6-tempered 6061 or 7075 series aerospace aluminum with the latter, 7075-T6, being the most preferred and common these days.

In the match-off between the two grades, 7075 is harder and stronger, leading to better tensile strength, fatigue strength, and shear strength compared to 6061. Most makers these days reserve 6061 for use as handguard materials and in charging handles, for which it is sufficiently strong.

Construction

There are also three separate ways of making uppers: cast (poured into a mold), forged (aluminum block hammered into shape), and billet (an aluminum block carved into its final shape by a CNC machine).

Of these, the cast type is the worst, as the process is prone to making a more brittle finished product due to inherent imperfections in the casting process.

Billet is the most expensive as it requires the most machining but produces the most aesthetically-pleasing designs. Forged uppers split the difference while providing a strong component for a decent price.

Professionally completed forged or billet uppers made of decent quality 7075-T6 will basically last forever– provided properly loaded ammo is used and in-spec parts are installed on it– and can outlast several barrels and bolt carrier groups.

Tolerance stacking

A problem can occur when an M4 barrel– even a good-quality M4 barrel– and an M4 upper– even a good-quality M4 upper– will not mesh together properly.

This is when, for instance, the feed ramp of the barrel extension ramps overhangs the feed ramp extension of the receiver, producing a stop or ledge where the two meet. In situations like this, the receiver may have to be recontoured to mesh with the barrel seamlessly as the individual tolerances of the components, while they may have been superb by themselves, are out of range when mated.

If suffering feeding issues on your new M4 build, such as nosediving, odds are you may want to check for this fitment between the two components. One way around this is to get an M4 upper that already has the barrel installed and tested by the manufacturer, thus in theory evening out the feed ramps.

Sources

- ATF, Firearms Commerce in the United States, 2011, Pg 22

Sign up for our newsletter

Get discounts from top brands and our latest reviews!