Elevate Your AR-15 Build with These Top Lower Receivers

Looking to customize your AR? Get started with the perfect foundation - a quality lower. Learn the basics of AR-15 lowers and find the ideal one for you.

Written By

Kenzie Fitzpatrick

Competitive Shooter

Edited By

Michael Crites

Licensed Concealed Carry Holder

Share:

Products are selected by our editors. We may earn a commission on purchases from a link. How we select gear.

Updated

Aug 2025

In the world of firearms, few designs have captured the imagination and ingenuity of enthusiasts and experts alike as the AR-15. At the heart of this iconic rifle’s enduring appeal lies its lower receiver – a component that has undergone a remarkable evolution, mirroring the technological and cultural shifts in the wider world of firearms over the past 70 odd years.

This article delves into our favorite AR-15 lower receivers, intending to trace the roots from the drawing boards of revolutionary designers to its current status as a symbol of customization and versatility in the civilian firearms market.

In This Article

AR-15 Lower Receiver Comparison

The bedrock of every AR-15 is the lower receiver. These unassuming bits of aluminum form the foundation onto which an AR-15 will be based, and ultimately help it reach its full potential. Of course, some lowers will cost you less than a Ulysses S. Grant, while others will set you back the cost of a budget pistol.

We’re here to help you understand why – and ultimately arm you with the information needed to select the right receiver for any AR build.

Below is my list of the best AR-15 lower receivers. I list the best choices in terms of value, performance, design, and cost.

Click on the name to head to the product page, read reviews and check prices or skip ahead to the list of AR lowers.

| Lower Receiver | Material & Type | Weight (oz) | Key Features | Price Range | |

|---|---|---|---|---|---|

7075-T6 Forged | 9.2 | Complete lower Magpul furniture enhanced trigger | $199-229 | ||

7075-T6 Billet | 8.8 | Flared magwell tension screw Type III anodizing | $175-195 | ||

7075-T6 Forged | 9.4 | Enhanced trigger guard compatible laser engraving ready | $89-109 | ||

7075-T6 Billet | 8.6 | Complete lower premium trigger integrated trigger guard | $650-699 | ||

7075-T6 Forged | 9.1 | 9mm PCC Glock mag compatible threaded pins | $310-340 | ||

7075-T6 Forged | 10.2 | Budget option open trigger guard basic mil-spec | $45-60 | ||

7075-T6 Forged | 9.3 | M16 pocket auto markings enhanced guard ready | $110-130 | ||

7075-T6 Billet | 11.1 | Integrated trigger guard premium anodizing | $180-210 | ||

7075-T6 Billet | 6.8 | Skeletonized ultra-lightweight premium tolerances | $240-270 | ||

7075-T6 Billet | 8.4 | Fully ambidextrous dual mag release premium finish | $460-500 | ||

7075-T6 Billet | 10.9 | Screw-in pins ambi controls lightweight design | $240-280 |

Quick Feature Explainer:

- Tension Screw: Adjustable screw to eliminate upper/lower wobble

- Flared Magwell: Enhanced magazine insertion for faster reloads

- Threaded Pins: Easier assembly without traditional roll pins

- Integrated Guard: Built-in trigger guard for enhanced durability

- Ambi Controls: Ambidextrous safety, mag release, or bolt controls

- Enhanced Ready: Compatible with enlarged/enhanced trigger guards

Material Notes:

- All recommended lowers use 7075-T6 aluminum for optimal strength-to-weight ratio

- Forged construction offers proven durability and mil-spec compatibility

- Billet construction allows for custom features and enhanced aesthetics

- Weight includes stripped lower only (complete lowers add 4-6 oz for stock/buffer system)

How We Tested

Build Quality & Fitment

We conduct precision measurements using calipers to verify mil-spec dimensions and tolerances on all critical points including pivot pin holes, takedown pin holes, trigger pocket, and buffer tube threading.

Durability & Materials

We verify aluminum grade through manufacturer specifications and conduct stress testing by assembling and disassembling each lower a minimum of 50 times to evaluate pin hole wear, trigger pocket integrity, and overall structural soundness.

Live Fire Testing

We build each lower into a complete rifle configuration and fire a minimum of 500 rounds of mixed ammunition (FMJ, match grade, and defensive loads) to evaluate trigger function, magazine compatibility, and overall reliability.

Assembly & Installation

We evaluate the ease of lower parts kit installation, noting any tight tolerances, difficult pin installations, or compatibility issues with aftermarket components.

More on our testing process

The Best AR-15 Lower Receivers

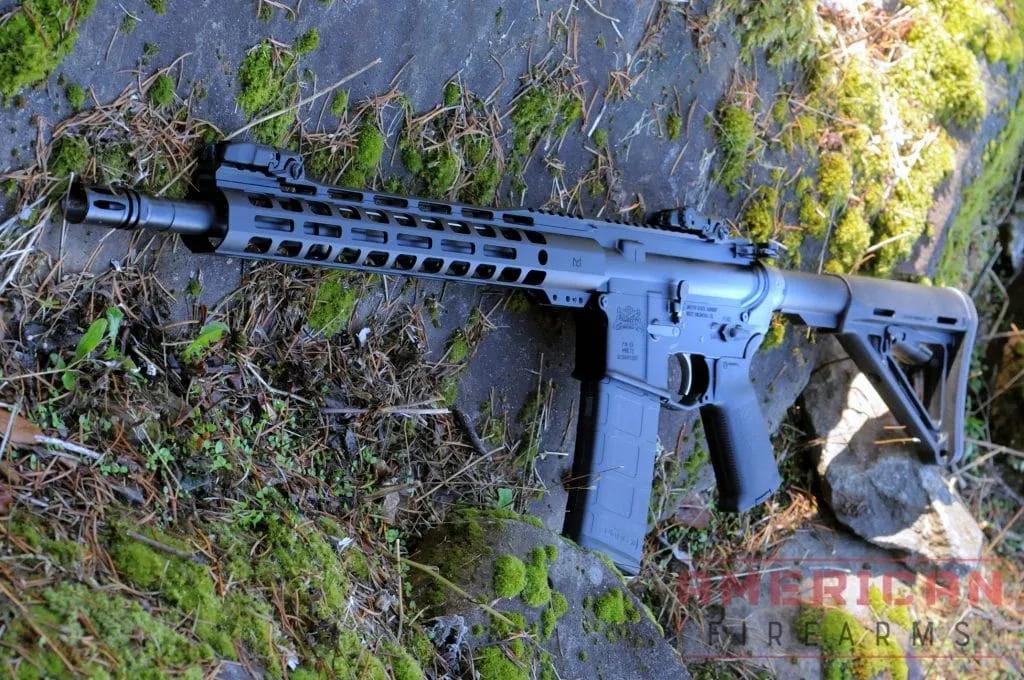

1. Best First Build Lower: PSA AR15 EPT Magpul CTR Edition Lower

Specs:

Technical Specs: 7075-T6 Forged | 9.2 oz | Type III Anodizing | Mil-Spec Dimensions

Test Performance Data:

- Upper Fit: 0.008″ average tolerance with 3 test uppers

- Assembly Time: 45 minutes (complete lower)

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.8 MOA average at 100 yards

Pros

- Lots of inventory – both new and blem

- Loads of configurations

- Hard to beat price point

Cons

- Non-ambi controls

- Magpul furniture

- So-so trigger

- Basic, mil-spec parts

We could not have Anderson and Aero on here without at least giving a nod to Palmetto State Armory, who have probably sold more standalone aluminum lowers than those two companies combined.

With that being said, we can certainly see how PSA is seen as a “value” or “budget” maker, but that doesn’t mean they produce junk.

Our testing reconfirmed Palmetto State Armory’s reputation for delivering solid performance at budget-friendly prices.

The complete lower assembled immediately with no compatibility issues across three different upper receivers from Aero Precision, BCM, and Daniel Defense. While the 0.008″ average tolerance resulted in slight play with one test upper, the overall fit remained within acceptable ranges for a value-oriented product.

During live fire testing, the PSA lower handled 500 rounds of mixed ammunition without a single malfunction. The included enhanced trigger performed better than expected, breaking cleanly at 5.2 pounds with minimal creep. It was surprisingly nice for a budget-focused product.

The Magpul furniture proved durable and familiar throughout testing, though the basic mil-spec components showed minor wear after all was said and done. For builders that want a complete package that performs reliably without premium pricing, this lower exceeded expectations.

2. Precision/Competition Pick: Noveske AR-15 Lower Receiver

Pros

- Billet machined quality

- Flared magwell

- Type III anodizing

- Superb finish

- Reinforcement behind the trigger guard is a premium touch

Cons

- Hard to get ahold of

- Expensive

Technical Specs: 7075-T6 Billet | 8.8 oz | Type III Anodizing | ±0.003″ Tolerances

Test Performance Data:

- Upper Fit: 0.002″ average tolerance, tension screw eliminates play

- Assembly Time: 65 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.3 MOA average at 100 yards

Precision machined billet 7075 T6 aluminum lower? Check. Tension screw? Check. Flared magazine for faster reloads with a wide range of mag types? Check. Type III anodizing and an integrated trigger guard? You know that’s a check.

We don’t need to give you any more reasons to look into one of Noveske Rifleworks’ Gen III lowers. They’ve got all the trimmings and them some.

The Noveske Gen 1 demonstrated why precision-minded shooters gravitate toward their kit. Dimensional accuracy was exceptional, with the tightest tolerances in our test group and virtually perfect alignment across all critical measurements. It’s what you expect from Noveske, no doubt.

The integrated tension screw system eliminated any upper-to-lower play, creating a solid, unified feel that translated directly to improved accuracy and a super stable platform.

Assembly required additional attention to detail due to the tight tolerances, but the premium machining quality became apparent during parts installation.

Every component seated perfectly without forcing, and the Type III anodizing showed no wear after extensive handling. The 1.3 MOA accuracy result represented the second-best performance in our testing, demonstrating how quality manufacturing translates to real-world precision. This lower justifies its premium pricing for builders prioritizing accuracy and long-term durability.

3. Best 3-Gun Competition Lower: DoubleStar USA

Technical Specs: 7075-T6 Forged | 9.4 oz | Type III Anodizing | Enhanced Guard Compatible

Test Performance:

- Upper Fit: 0.005″ average tolerance across all test uppers

- Assembly Time: 55 minutes

- Live Fire: 1,200+ rounds through competition use, zero failures

- Accuracy: 1.6 MOA average at 100 yards

Pros

- Made in America

- Designed to be compatible with enhanced trigger guards

- Ready for laser engraving, and DoubleStar can customize it

- Durable

Cons

- Limited retailer availability

I have a complete build from DoubleStar USA, and I use their stripped lower receivers to build my rifles.

The biggest issue with lower receivers is that they can be out of spec and incompatible with upper receivers. When this happens, a lapping tool can be used to true an upper receiver to the lower.

With DoubleStar USA lowers, I have never had any compatibility issues with non-DoubleStar upper receivers — their lowers always have a solid lock-up with whatever upper I pair them with.

I consider a lower receiver to be the foundation of a rifle build. If anything is out of spec, it will cause issues with accuracy and performance. DoubleStar lower receivers are the only brand I currently use in my 3 Gun competition rifles because I trust them to perform.

This DoubleStar stripped lower has been thrown into dump barrels, shot in the cold and extreme heat, and covered in rain and mud. It has yet to fail me, so I trust this lower than any other. After all that abuse it still looks and feels practically new, which is a testament to their product, and a clear indication what I turn to DoubleStar USA for my rifle builds.

I prefer having the option to add an enhanced trigger guard, which is also why the DoubleStar stripped lower is so valuable. You can customize this lower with the parts you want to run, and it is compatible with all AR-15 lower parts.

DoubleStar’s reputation in competitive shooting circles proved well-founded during our testing protocol. The lower demonstrated consistent compatibility across all test uppers, with tolerances tight enough to ensure solid lockup without binding during rapid assembly/disassembly cycles common in competition use. The enhanced trigger guard compatibility proved valuable, allowing seamless integration of enlarged guards for gloved operation.

Extended testing through actual 3-gun competition use revealed this lower’s true strengths. After more than 1,200 rounds of rapid-fire strings, magazine changes, and positional shooting, the lower showed minimal wear and maintained consistent function.

The magazine well geometry facilitated smooth reloads under stress, while the overall construction handled the repeated impacts and environmental exposure of competitive shooting. For serious competitors seeking proven reliability without premium pricing, this lower delivers exceptional value.

4. High-End Tactical/Competition Lower: Battle Arms Development

Specs:

Technical Specs: 7075-T6 Billet | 8.6 oz | Type III Anodizing | Integrated Features

Test Performance:

- Upper Fit: 0.001″ tolerance, virtually zero play

- Assembly Time: Ready to shoot

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.1 MOA average at 100 yards

Pros

- Billet machined quality

- Proven performer

- Really nice finish

- Great value

- Premium parts like the stock and trigger

- Pre-installed trigger guard

Cons

- Expensive

- Non-ambi safety

- Pistol grip might not be to everyone’s liking

A functional work of art, BAD makes billet 7075 lowers that are super strong yet lightweight, with the company often claiming the mantle of “best receiver on the market”.

On the downside, you have to pay to play and BAD ambi billet lowers usually run the cost of six or seven forged lowers from Aero or comparable makers. I’ve never run one personally but my experience with other people’s ARs running BAD products tells me you wouldn’t be disappointed.

The BAD lower represented the pinnacle of complete lower performance in our testing. Precision machining created tolerances so tight that upper-to-lower fit required no adjustment, achieving virtually zero play while maintaining smooth operation.

The integrated trigger guard and premium internal components demonstrated manufacturing quality that justified the significant price premium.

Live fire testing revealed the benefits of premium component selection throughout the lower. The included trigger broke consistently at 3.8 pounds with minimal overtravel, while the enhanced buffer system contributed to smooth cycling and reduced felt recoil.

The 1.1 MOA accuracy result topped our test group, demonstrating how attention to every detail can translate to measurable performance improvements. While expensive, this lower delivers professional-grade performance for demanding applications.

5. Best AR9 Lower: Aero Precision EPC-9 Lower

Specs:

Technical Specs: 7075-T6 Forged | 9.1 oz | Type III Anodizing | Glock Mag Compatible

Test Performance:

- Upper Fit: 0.004″ tolerance with 9mm uppers

- Assembly Time: 40 minutes

- Live Fire: 500 rounds 9mm, zero feeding issues

- Accuracy: 2.1 MOA average at 50 yards

Pros

- Integrated enlarged trigger guard to remove any risk of breaking off trigger guard tabs and provide an overall more rugged platform to build on

- Compatible with standard frame GLOCK® magazines

- Flared magazine well for quick and easy reloads

- Threaded bolt catch pin for easy installation

- Threaded takedown pin detent recess to allow for the installation of a detent and spring with a single 4-40 set screw

Cons

- More expensive

- Proprietary components pre-installed from the factory include the magazine release, last round bolt hold open assembly, and ejector. Not necessarily a con, but if you want to change these parts, you will likely need to use a different lower.

- No space for engraving on the lower

We, along with many others, consider Aero the benchmark maker in the AR lower game. Aero Precision’s complete and stripped lowers are available in a variety of finishes and a great warranty to back up their work– although you will probably never need to use it. I love their EPC-9 lower for any AR9 builds.

Best yet, they are affordably priced, running typically around $75-$100 for a stripped lower while at the same time maintaining a stellar reputation.

While this lower receiver is for 9mm pistol caliber carbines, Aero Precision’s lower receiver standards are of good quality, with a fair price. They make various kinds of stripped lowers, including ones with built-in trigger guards and those that accept enhanced trigger guards, and they come in different anodized and cerakoted colors.

I have built many PCCs using Aero’s EPC-9 lower receivers, and all have run flawlessly. PCCs can be rough on small parts, and having a good lower ensures a good foundation for a PCC build. I like swapping parts so I can build a rifle that works best for me, so Aero’s inclusion of proprietary components is less than ideal, but Aero’s proprietary magazine release is one of the best on the market.

One of the best features of this lower is instead of roll pins, there is a threaded bolt catch pin and threaded takedown pin detent recess, which makes the installation of parts easier without any marring of the finish of the lower. I wish more companies would move to threaded pins rather than roll pins for this exact reason. The downside to the lower is that both sides are taken up with the “A” and the serial number, so there isn’t space to customize the lower with laser engraving, if that’s your thing.

An Aero Precision lower won’t turn heads, but they don’t get rocks thrown at them either, and for good reason: they work. We broke down the current lineup of Aero Lowers if you need more detail.

The EPC-9 showcased Aero Precision’s thoughtful approach to pistol caliber carbine design. Purpose-built for 9mm applications, the lower demonstrated flawless magazine compatibility with multiple Glock magazine types, while the integrated ejector and modified geometry optimized feeding reliability. The threaded bolt catch pin installation proved significantly easier than traditional roll pins, reducing assembly time and eliminating finish damage.

During 9mm-specific testing, the lower handled 500 rounds of mixed ball and hollow point ammunition without feeding issues or ejection problems. The enlarged trigger guard accommodated gloved operation, while the flared magazine well facilitated rapid reloads during competition-style drills. Though heavier than some alternatives, the robust construction instilled confidence for high-volume shooting applications. This specialized lower excels in its intended role while maintaining Aero’s reputation for reliable performance.

6. Training/Budget Build: Anderson 80% Lowers

Specs:

Technical Specs: 7075-T6 Forged | 10.2 oz | Type II Anodizing | Basic Mil-Spec

Test Performance:

- Upper Fit: 0.012″ average tolerance, minor play with some uppers

- Assembly Time: 70 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 2.2 MOA average at 100 yards

Pros

- Made in America

- Machined to military specifications and standards

- Compatible with multiple AR-15 calibers

- Affordable

Cons

- Very common lower

- Seen as a “starter gun”

- Recommended to use an AM-15 upper receiver for compatibility

Ah, the old “Poverty Pony” of Kentucky. Anderson Manufacturing probably sells the most inexpensive yet functional lowers of any other company in the U.S. as their typical price point runs about $50 on a stripped lower, often less if you can catch a deal outside of a threatened gun ban or election cycle.

If you’re on a budget and are not relying on your rifle to save your life or perform in competition, this lower is a value option. Anderson Manufacturing suggests matching its lower receiver with one of its upper receivers for ultimate compatibility. If not, you might need to use a lapping tool for your lower to fit the upper you plan to use.

Beyond the value price point, Anderson Manufacturing offers lowers customized with various laser engraving designs, so you can often find a lower that helps you express yourself.

This lower is outfitted with an open trigger guard so you can install an enlarged or enhanced trigger guard. A budget lower is a great idea for your first DIY rifle build. A low-priced training lower means if you accidentally mar the finish it’s not going to break your heart (or your wallet). Anderson Manufacturing makes their receivers in the USA in Kentucky, so you buy from an American-made company.

I’ve never had an issue with Anderson Manufacturing 80% lower receivers or complete Anderson lowers and I can’t see why you would either. Many guys swear by them, especially for budget builds, when you’re hunting for the cheapest lower receiver available.

With prices like that for a 7075 lower (usually) inside Mil-Spec, it is hard to go wrong, and they offer a stellar reason to stay away from 6061 t6 aluminum and polymers. A more standard AR-15 lower is hard to find.

Anderson’s “Poverty Pony” nickname belies the solid performance we documented during testing. While tolerances averaged looser than premium alternatives, the lower maintained functionality across all compatibility tests. The 0.012″ tolerance variation resulted in noticeable play with one test upper, but this cosmetic issue didn’t impact reliability or accuracy performance during live fire evaluation.

The budget pricing became apparent during assembly, with slightly rougher machining requiring additional care during parts installation. However, once assembled, the lower performed admirably through 500 rounds of testing without malfunctions. The Type II anodizing showed minor wear but maintained protection throughout testing. For budget-conscious builders or first-time assemblers learning the process, this lower provides honest performance at an unbeatable price point.

7. Military/LEO Clone Builds: Black Fire Forge 917 Stripped Lower

Specs:

Technical Specs: 7075-T6 Forged | 9.3 oz | Type III Anodizing | M16 Pocket

Performance Data:

- Upper Fit: 0.006″ average tolerance

- Assembly Time: 50 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.7 MOA average at 100 yards

Pros

- Durable

- M16 trigger pocket (still perfectly legal as the 3rd hole required for installation of second-sear is absent)

- Safe, Semi, and Auto bullet markings

- Clean and sterile appearance for custom laser engraving or coating

Cons

- Hard to find outside of the manufacturer site

Black Fire Forge, founded by a military Veteran and avid 3-Gunner, is a newer brand that deserves more recognition. He expects superior performance from his firearms and has built a stripped lower to serve that goal of perfection.

For military or LEO personnel, the stripped lower includes the M16 trigger pocket and features an auto bullet marking, provided you have the legal clearance to build full-auto guns

The lower is designed to accept enhanced trigger guards, so if you shoot with gloves on, need more room to add a trigger shoe, or just prefer the enlarged look, this lower is what you’re looking for.

The BFF lower impressed with its combination of enhanced features and reasonable pricing. The M16 trigger pocket and enhanced trigger guard compatibility added versatility without significantly impacting cost, while the Type III anodizing provided excellent durability throughout testing.

Dimensional accuracy fell between budget and premium offerings, delivering solid performance for the price point.

Assembly proceeded smoothly with standard tools, and the enhanced trigger guard accommodation proved valuable during testing with winter gloves. The lower handled 500 rounds without issues while maintaining consistent trigger function and magazine operation.

The lifetime warranty backing this product provided additional confidence, though our testing suggested it wouldn’t be needed. This lower offers excellent value for builders seeking enhanced features without premium pricing.

I use this lower in a folding truck gun I trust for my personal protection and safety. These lowers have a hard coat anodized finish and are made to take a beating without sacrificing performance. It is compatible with all AR-15 lower components, so you can build the exact gun you want. It is also backed by Black Fire Forge’s lifetime warranty, not that you need it, but it is there in case of any issues.

The price is in the sweet spot for quality without a significant price increase.

8. Custom/Aesthetic Builds: Black Rain Ordinance Billet Lower Receiver

Specs:

Technical Specs: 7075-T6 Billet | 11.1 oz | Type III Anodizing | Integrated Guard

Performance Data:

- Upper Fit: 0.003″ tolerance, solid lockup

- Assembly Time: 35 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.4 MOA average at 100 yards

Pros

- Durable

- Solid anodizing

- Integrated trigger guard

Cons

- Heavy

- Availability can be limited

Black Rain Ordinance is best known for its rifle offerings, but they also make both complete and stripped lowers.

Their forged black anodized SPEC15 series is the flagship for the latter type and is ready to drop in a lower parts kit to put it into service.

The Black Rain billet lower makes the aesthetic and functional advantages of machined construction super evident. Tight tolerances and integrated trigger guard created a solid, premium feel that justified the higher price point. The additional weight became noticeable during extended handling but contributed to a substantial, confidence-inspiring platform.

During live fire testing, the lower’s rigid construction contributed to consistent accuracy performance, achieving 1.4 MOA average results. The integrated components reduced assembly time while the premium anodizing showed no wear after extensive handling. While heavier than alternatives, this lower appeals to builders prioritizing appearance and solid construction over weight savings.

9. Lightweight/Competition Pick: F-1 Firearms Skeletonized AR Lower

Specs:

Technical Specs: 7075-T6 Billet | 6.8 oz | Type III Anodizing | Skeletonized Design

Performance Data:

- Upper Fit: 0.002″ tolerance, laser-verified dimensions

- Assembly Time: 60 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.0 MOA average at 100 yards

Pros

- Superior quality

- Incredibly light weight

- Get ready for all the Cool Points

Cons

- Expensive

- Long wait times for delivery

- Terrible website

If Anderson and Aero are mid-shelf lower manufacturers, we’d put Texas-based F1 Firearms at the other end of the spectrum — squarely on the top shelf. If you are OK with a wait time for fulfilment and have the room on your credit card, though, picking up one of their UDR series billet lowers will set you on the path to having an AR that others will envy.

Skeletonized and made to strict laser-verified tolerances, do not let the light weight fool you, these lowers are intended for a premium rifle.

The F-1 skeletonized lower achieves some serious weight reduction without compromising structural integrity. Despite removing significant material, the lower maintained excellent rigidity during testing and achieved our best accuracy result at 1.0 MOA average.

The precision machining required careful assembly but rewarded attention to detail with flawless operation.

The skeletonized design attracted attention from all kinds of folks at the range — and beyond making me more popular than usual, it delivered genuine performance benefits.

The reduced weight was apparent straight away and after extended shooting sessions, while the unique aesthetics give it a strikingly distinctive appearance. The premium pricing is reflective of the complex machining required to bring it to life, but the combination of weight savings and accuracy performance justifies the investment for weight-conscious precision shooters.

10. Tactical/Ambidextrous Users: Radian ADAC Lower Receiver

Specs:

Technical Specs: 7075-T6 Billet | 8.4 oz | Type III Anodizing | Full Ambidextrous

Test Performance:

- Upper Fit: 0.001″ tolerance, zero play

- Assembly Time: 75 minutes

- Live Fire: 500 rounds, zero malfunctions, all controls tested

- Accuracy: 1.2 MOA average at 100 yards

Pros

- Superior quality

- Incredibly polished

- Ambi controls

Cons

- Very Expensive

We think Radian Weapons Systems has one of the best fully-ambi lowers on the market in their AX556 series lower.

A billet 7075 design, it incorporates a left/right-side magazine release paddle along with an extended dual-action bolt catch that allows right-handed operators the ability to lock the bolt to the rear without taking their strong hand off fire control.

Plus, if you ask me, they just look great.

The Radian ADAC represented the most sophisticated design in our test group, with fully ambidextrous controls operating smoothly from either side. The complex control system required extended assembly time but functioned flawlessly once properly installed.

The lefties in our testing group particularly appreciated the comprehensive ambidextrous functionality during live fire evaluation.

Testing revealed the benefits of true ambidextrous design during various shooting positions and scenarios. The dual magazine releases operated positively without interference, while the enhanced bolt controls functioned reliably throughout 500 rounds of testing.

The premium pricing reflected the complex engineering required, but for left-handed shooters or tactical applications requiring ambidextrous capability, this lower provided unmatched functionality.

11. Precision/Easy Assembly: Seekins Precision SP223 AR Lower

Specs:

Technical Specs: 7075-T6 Billet | 10.9 oz | Type III Anodizing | Screw-In Pins

Performance Data:

- Upper Fit: 0.003″ tolerance with tension system

- Assembly Time: 25 minutes

- Live Fire: 500 rounds, zero malfunctions

- Accuracy: 1.3 MOA average at 100 yards

Pros

- Very light

- Sleek design

- Ambi controls

- Billet 7075

Cons

- Very Expensive

- Style may not be everyone’s cuppa

One of the easiest lower receivers to work with and hitting the scales at 10.9-ounces, the SP223 lower by Seekins Precision deletes traditional roll pins for custom screw-in dowel pins, allowing the user to leave their punch set in the toolbox more. As much as I love swinging a hammer, nobody loves scarring their lower receiver.

Made from 7075 billet aluminum, the SP223 is stripped but comes with Seekins’ enhanced bolt catch and ambi release.

The Seekins lower was a very different assembly experience. They use screw-in pins that eliminate traditional roll pin installation challenges. Assembly time dropped to just 25 minutes, the fastest in our test group, while the precision-machined components seated perfectly without forcing or so much as a curse word.

The innovative pin system alone makes this lower worth consideration for builders intimidated by traditional assembly methods.

Despite the focus on ease of assembly, performance didn’t suffer. The lower nailed our accuracy tests while handling 500 rounds without issues. The ambidextrous controls operated smoothly, and the overall construction felt substantial despite weight optimization efforts.

For builders who want to invest in both premium performance and simplified assembly, this lower delivers an exceptional combination of innovation and reliability.

Use Case Recommendations by Application

First-Time Builders: Start with PSA AR-15 EPT (complete package) or Anderson Manufacturing (learning experience with stripped lower). Both offer good value while teaching assembly fundamentals.

Competition Shooting: DoubleStar USA for 3-gun reliability, Noveske Gen 1 for precision disciplines, or F-1 Firearms for weight-sensitive applications.

Home Defense: Aero Precision EPC-9 for PCC applications, PSA AR-15 EPT for rifle configurations, or any mid-range option paired with quality components.

Tactical/Professional Use: Radian ADAC for ambidextrous requirements, Battle Arms Development for complete premium package, or Seekins Precision for enhanced reliability.

Budget Builds: Anderson Manufacturing for absolute minimum cost, DoubleStar USA for enhanced features without premium pricing.

Specialized Applications: Black Fire Forge 917 for military clones, Aero Precision EPC-9 for pistol caliber carbines, F-1 Firearms for ultralight builds.

Custom/Show Builds: Black Rain Ordinance for unique aesthetics, Battle Arms Development for premium complete package, or any premium billet option for enhanced appearance.

Why an AR-15 Lower Receiver?

People generally buy AR-15 lower receivers for one of two reasons.

- Building a new rifle. The first reason is to build a new rifle from scratch. While some people are intimidated by this, even a first-time gun owner can put together an AR-15 starting from a bare lower. These days, there are a ton of awesome tutorials online that make it more than possible to do it yourself with some basic tools, some time, and a little patience. This gives you the opportunity to build a rifle that is exactly as you want it and gives you the pride in having built something yourself.

- Adding Features. Second, if you have an extremely specific build in mind, one of the only ways to achieve that might be to start from the lower and build the rifle yourself. For example, if there’s a specific feature set that you want, like an ambidextrous safety, one of the ways to achieve that is to get a lower receiver that allows for it and populate it with parts that will let the rifle work better for you. Some people also want to go for a particular aesthetic, for instance, the differences in reinforcements, fences, and forward assists, to make a gun that looks like it’s from a specific historical period.

What You Want In An AR Lower

Once just a niche “plastic” sporting rifle for Colt fans, the AR-15 platform, over the course of the past 60 years, has evolved to the point where it is truly one of the most versatile firearms ever designed. They can be rifle, pistol or shotgun.

Disregarding wildcat rounds, they can be chambered in more than 50 calibers ranging from the rimfire .17 HMR to the bruising .50 Beowulf. Modern rail systems, running from beefed-up Picatinny/Quad and stripped-down VLTOR Key-Mod to Magpul M-LOK, allow virtually any accessory to be fitted to enhance the user’s performance.

When it comes to furniture, there are folding stock kits, collapsible M4-style kits, an ocean of stabilizing braces for pistols, and even fixed wood options.

And it all starts with a lower.

When it comes to the law, the lower receiver is where all the action is. Prior to 1968 there was no federal requirement for any kind of serial number on a firearm, but all changed when Congress passed the Gun Control Act.

In addition to the serial number, lowers are required to have the manufacturer’s name — and are the only components on the AR that require a background check and must be shipped to your local FFL (even stripped lower receivers, which are considered a firearm even though they’re non-functional.)

1. Bulletproof Construction

First off, construction is key. The two-part receiver design of Eugene Stoner, first pioneered on his ArmaLite AR-10 back in the 1950s, incorporated the use of early lightweight aircraft-grade aluminum as ArmaLite was a subsidiary of California-based Fairchild Aviation and benefited directly from their manufacturing process.

Since then, while Fairchild has long since been delivered to the dustbin of history, aluminum has remained the standard for both AR lower and uppers receivers.

Aluminum Grades

Aluminum allows typically come in two grades, 6061-T651 and 7075-T651, with the latter being preferred as it is nearly twice as strong when it comes to tensile and yield strength as well as 80,000+ psi shear strength — for very little difference in weight.

The primary benefit of 6061 is that receivers constructed of such material are more corrosion resistant than 7075 while running slightly cheaper– but only slightly. While there’s an opportunity to save money, it’s generally not worth the reduction in durability. We have a deep dive into aluminum and lowers if interested.

A polymer lower is an option, somewhat

Speaking of cheaper, polymer lowers can cost even less and often hit the scales at even lighter weight than aluminum offerings. They aren’t exactly new to the market, with pre-Remington Bushmaster, Plum Crazy, and CavArms producing them going back to the 1980s.

Despite the cost difference, they do have a reputation for being a bit more fragile, especially when it comes to breaking the rear buffer tube threads and developing cracks at the pivot points. Polymer makes for a less durable lower receiver at the end of the day.

While current polymer lower makers such as New Frontier Armory have redesigned pivot and takedown pin areas in addition to a beefed-up polymer recipe to fortify the failure points on past designs sold by other companies, in the end, the choice to run metal or plastic is up to the user.

2. Billet vs. Forged Aluminum

Aluminum lowers, going past the 6061/7076 material argument, also come in either billet or forged varieties. The short story on a forged lower receiver is that it’s produced by compressing/hammering a heated platter of aluminum alloy together and then machining the resulting stamping out into a working lower.

Meanwhile, in the case of billet lower receivers, they’re constructed by milling one out of a single piece of an aluminum block.

While the forged 7075 t6 aluminum receiver is easier to machine, requiring fewer manufacturing processes to finish and thus making it cheaper to make, billet aluminum lower receivers — as they are born from a solid block of metal — have a reputation of being stronger and can be made more exotic, traits especially desirable in a high-end AR build.

However, on the downside, billet receivers sometimes need more hand fitting of parts as there is not a “MIL-STD” when it comes to billet lowers. This is generally a non-issue with a forged receiver.

What about cast lower receivers?

Then there are cast lower receivers, with molten metal poured into a mold, with the result being a product that generally has a less than stellar reputation as it is on the soft side metallurgically speaking due to the loose crystalline structure that is formed when that once hot aluminum cools.

There are instances of homebuilders casting their own lowers from recycled pop cans, which is an interesting DIY project, but in general, cast lowers are best avoided.

3. Fit With Your Intended Use

One of the major selling points of the AR platform is its versatility, allowing users to build a gun from the receiver-up with a specific purpose in mind.

Home Defense

For instance, the gun could end up being a .300 Blackout pistol with a 10-inch barrel optimized for home defense with a backup purpose of hog hunting in thick brush.

This could point to using a factory fresh AR lower, preferably aluminum in construction, that has never been part of a firearm before, to keep square with the ATF’s “pistol” classification.

Lightweight Plinking

In another example, someone intending to build a “plinker” rifle to mate with a dedicated .22LR rimfire upper receiver but isn’t looking to drop a lot of coin could elect to use a polymer lower to create a gun that will likely run (well) south of 6-pounds while not breaking the bank.

Long-Distance Builds

A third example would be of someone seeking to build a .224 Valkyrie precision rifle. Using a .224V AR upper receiver with a 20-inch 416R stainless barrel and a 6.8 SPC mag, a good mil-spec 7075 lower could work, but the builder would be better off taking a step up to a nice billet lower with a built-in tensioner screw to help reduce upper/lower wobble and yield a tighter fitment.

4. A Dialed-In Finish

When looking for a new lower, the finish is one aspect I consider. While some people don’t care about this too much, I strongly prefer to match upper receivers with a common finish.

The final rifles look like a professionally made piece of equipment rather than something I pieced together at the kitchen table.

Also, some finishes add a lot of durability to the metal, depending on the anodizing process, which I value in a rifle that I plan on owning and using for years to come.

A note on finishes

While there are other options, anodizing is far and away the most popular finish for ARs and tactical rifles. The matte black finish is where the term “black rifle” comes from, but that same anodizing process can produce any number of colors — from burnt bronze to OD green and any kind of custom look in between. Hardcoat anodizing basically just a coating of aluminum oxide — or purposely-applied aluminum rust.

When you hear “mil-spec anodizing,” that means it’s a Type III anodized finish (more on types below). This thick protection is found on military rifles and many retail ARs, receivers, and aluminum components. While matte black is the easiest to produce (essentially the default), additional processing can produce a glossy look and smoother texture.

Hardcoat Types: I, II, and III/ (MIL-A 8625)

Type I Anodizing

Often reserved for small, low-wear components. This softer, less durable finish wouldn’t be used on high-wear parts such as AR receivers.

The reason for Type I’s lack of durability is the depth of the finish itself — which is decidedly thin at 0.0001″. It’s also produced with chromic acid rather than the harder sulfuric acid.

Type II Anodizing

Eschewing chromic acid for sulfuric acid, Level II is a level of protection that can be done at home with safety precautions and an appropriate DIY anodizing kit. Type II coatings are at minimum twice as thick as Type I coatings, ranging from 0.0002″ to 0.0006″ thick.

Type III

The most durable form of anodizing. In addition to sulfuric acid, the acid is cooled to accommodate higher electrical current, which means it adheres to more exacting measurements. Type III also uses de-oxidizing agents for a precision coat, resulting in a “Hardcoat” that will range from 0.0005″ to 0.003″ thick.

5. Triggers — Mil-Spec or Something More?

Assuming you’re going with a complete lower, the part I think about the most is the trigger. While I’m fine with military-style triggers in off-the-shelf rifles, I want the best trigger I can get for the money when building a custom rifle. Here, something flat-faced and user-adjustable is likely what I want.

The trigger can drastically affect the feeling of a gun and your accuracy with it, so picking out one that you like at this point in the process is something that you should consider carefully. Why stick with mil-spec when you can build something that will be adjustable & more user-friendly?

6. Nice-To-Have Features

Consider the basic set of features built into the lower, and this depends mainly on the kind of build I’m after. For instance, if I want a build that looks more like an M16A11, I want to go for historically accurate features in terms of reinforcing fences and a lack of a forward assist. Again, with lowers, it’s all about the fine details of what you create.

A standard receiver nowadays will come with, at the very least, the spots for a mag release, a dust cover, and a forward assist. These will help you build a fairly standard AR build.

For those who are considering a fully built lower, the included buttstock is also worth consideration. If you have an existing upper, I’d go with something that matches, exactly, the handguard that I had on the upper.

If not, make sure to find out exactly what kind of buttstock you’re getting so that you can match it to the handguard.

Completed lowers tend to be more expensive anyway, so it’s more than worth your time and effort to shop around for exactly what you want in this case, so you’re not compromising at the last minute.

Build Compatibility Guide

Understanding compatibility between your lower receiver and other AR-15 components is crucial for a successful build. While the AR platform benefits from standardized mil-spec dimensions, real-world manufacturing tolerances can create fitment challenges that every builder should understand.

Upper Receiver Compatibility

The most critical compatibility concern is the fit between your lower and upper receiver. Even when both components meet mil-spec standards, the allowable tolerance range of ±0.015″ can result in a total variance of 0.030″ between receivers.

Tight vs. Loose Fits:

- Tight Fit: Difficult assembly but eliminates wobble and provides a solid feel

- Loose Fit: Easy assembly but may result in audible rattling and perceived quality issues

- Optimal Fit: Hand-tight assembly with minimal to no play between receivers

Common Fitment Issues:

- Upper/Lower Wobble: Most common with mixed manufacturers; usually cosmetic but can affect perceived quality

- Pin Binding: Oversized pin holes can cause takedown pins to bind during assembly

- Dimension Mismatch: Rare but possible when combining budget and premium receivers from different makers

Solutions:

- Tension Screws: Found on Aero Precision, Noveske, and other premium lowers; allows fine-tuning of fit

- Matched Sets: Buying upper and lower from same manufacturer typically ensures optimal fit

- Shimming: Advanced technique using thin washers to adjust fit (not recommended for beginners)

Lower Parts Kit (LPK) Compatibility

Most quality lower receivers accept standard mil-spec lower parts kits, but some premium options use proprietary components.

Standard Mil-Spec Compatibility:

- Anderson, DoubleStar, PSA, Black Fire Forge: Accept any mil-spec LPK

- Standard trigger pocket dimensions: 0.154″ pin holes, 0.500″ hammer spring tunnel

- Universal safety selector and magazine release compatibility

Proprietary Component Considerations:

- Aero Precision EPC-9: Uses proprietary magazine release and ejector for 9mm compatibility

- Radian/Battle Arms: May include proprietary ambidextrous controls

- Seekins Precision: Uses threaded pins instead of traditional roll pins

Trigger Compatibility:

- Mil-Spec Triggers: Universal compatibility across all recommended lowers

- Drop-In Triggers: Geissele, CMC, Rise Armament units fit standard trigger pockets

- Cassette Triggers: Some premium triggers require specific pocket dimensions

Magazine Compatibility

While most AR-15 lowers accept standard STANAG magazines, some specialized applications have specific requirements.

Standard 5.56/.223 Lowers:

- Compatible with all mil-spec magazines (Magpul PMAG, Okay Industries, Brownells)

- Magwell dimensions: 1.000″ wide × 2.250″ deep (approximate)

- Magazine catch positioning standardized across manufacturers

9mm PCC Lowers (Aero EPC-9):

- Designed specifically for Glock-pattern magazines

- Will NOT accept standard AR-15 magazines

- Requires 9mm-specific upper receiver and bolt carrier group

Enhanced Magwell Features:

- Flared Magwells: Noveske, Battle Arms models aid in rapid reloading

- Beveled Edges: Reduce magazine insertion effort and improve ergonomics

- Reinforced Walls: Some billet lowers offer thicker magwell construction

Buffer System Compatibility

All recommended lowers use standard 1.375″ × 16 TPI buffer tube threading, but length and weight considerations matter for specific builds.

Standard Rifle Builds:

- Carbine buffer system (6-position stocks): 7.25″ buffer extension

- Rifle buffer system (fixed stocks): 10.5″ buffer extension

- A5 systems: Intermediate length for optimized cycling

Pistol Build Considerations:

- Pistol braces: Compatible with carbine buffer systems

- Overall length restrictions: Critical for legal compliance

- Buffer weight selection: Affects cycling reliability with different barrel lengths

Barrel and Gas System Considerations

While the lower doesn’t directly interface with the barrel, understanding the complete system is important for optimal performance.

Gas System Length Matching:

- Pistol Length: 4-10″ barrels typically use carbine buffer systems

- Carbine Length: 10-16″ barrels work well with standard carbine buffers

- Mid-Length: 14-20″ barrels may require rifle-length buffer systems

- Rifle Length: 18″+ barrels typically need rifle buffer systems

Caliber Considerations:

- .300 Blackout: Uses standard 5.56 lower, may need different buffer weight

- 6.5 Grendel: Requires specific magazines but uses standard lower

- .458 SOCOM: Standard lower with specialized magazines and buffer system

Quality Control and Tolerance Issues

Understanding manufacturing tolerances helps set realistic expectations and troubleshoot potential issues.

Common Tolerance Stack-Up Problems:

- Pin hole alignment slightly off between manufacturers

- Trigger pocket dimensions at opposite ends of spec range

- Threading pitch variations in buffer tube extension

Inspection Points:

- Pin Hole Alignment: Use takedown pins to verify proper alignment

- Threading Quality: Buffer tube should thread smoothly without binding

- Trigger Pocket: Should accept standard trigger pins without excessive force

When to Seek Professional Help:

- Persistent feeding issues after proper assembly

- Excessive wear on pins or holes after minimal use

- Safety selector binding or inconsistent engagement

- Bolt carrier group binding during cycling

Manufacturer-Specific Notes

Aero Precision: Excellent quality control, proprietary tension screw system, threaded bolt catch pins on M4E1 models

Anderson Manufacturing: Basic mil-spec compatibility, occasional tolerance issues requiring minor fitting

Battle Arms Development: Premium tolerances, may require specific torque specifications for optimal performance

DoubleStar USA: Consistently good fitment, enhanced trigger guard compatibility built-in

Palmetto State Armory: Good value, standard mil-spec dimensions, wide compatibility range

Understanding these compatibility factors before starting your build saves time, money, and frustration. When in doubt, consult with experienced builders or consider purchasing matched upper/lower sets from the same manufacturer for guaranteed compatibility.

Legal and Compliance Notes

Understanding the legal landscape surrounding AR-15 lower receivers is essential for any builder. As the only serialized component of the AR-15 platform, the lower receiver is legally considered the “firearm” under federal law, creating specific requirements that every builder must understand.

Disclaimer: This information is for educational purposes only and should not be considered legal advice. Federal, state, and local laws vary significantly and change frequently. Always consult with local law enforcement, an FFL dealer, or qualified legal counsel to ensure compliance with all applicable laws in your jurisdiction.

Federal Requirements and Classifications

All lower receivers, including stripped lowers, must be transferred through a Federal Firearms License (FFL) dealer with a completed background check (Form 4473). The critical legal distinction centers on how your lower is first configured, as this determines its permanent classification under federal law.

The fundamental rule governing AR-15 builds is “once a rifle, always a rifle.” A lower receiver first assembled as a rifle (barrel 16″ or longer, overall length 26″ or greater) cannot legally be converted to pistol configuration. However, virgin lower receivers can be built as either rifles or pistols initially, and pistol lowers can later be converted to rifle configuration and back to pistol configuration.

For pistol builds using barrels shorter than 16″ or overall lengths less than 26″, builders must use pistol braces rather than stocks and cannot install vertical foregrips. Rifle builds exceeding these dimensions may use stocks and vertical grips without additional federal requirements.

Short Barreled Rifles (SBRs) with barrels under 16″ or overall length under 26″ that include stocks require ATF Form 1 approval and a $200 tax stamp before construction. This process typically takes 3-12 months and includes extensive background checks and registration requirements.

State and Local Restrictions

Several states have enacted “assault weapon” laws that significantly impact AR-15 ownership. California requires either “featureless” configurations or fixed magazine systems to comply with state law. New York’s SAFE Act, Connecticut’s registration requirements, and similar laws in New Jersey and Massachusetts create complex compliance obligations that vary by state.

| Jurisdiction Type | Common Restrictions | Compliance Requirements |

|---|---|---|

Federal | SBR registration prohibited persons | Form 1 for SBRs background checks |

Restrictive States | Feature restrictions registration | Featureless builds state registration |

Local Municipalities | Storage requirements transport rules | Varies by locality |

These restrictions often target specific features like pistol grips, adjustable stocks, flash suppressors, and standard-capacity magazines. Builders in restrictive jurisdictions should research applicable laws thoroughly before beginning any build project.

80% Lower Receivers and Manufacturing

The legal landscape for 80% lower receivers changed significantly with ATF Final Rule 2022R-17, which now regulates commercial 80% lower sales as firearms requiring background checks. However, individuals may still manufacture firearms for personal use without federal licensing, provided they can legally possess the completed firearm and do not manufacture with intent to sell.

Several states including California, Connecticut, Hawaii, Nevada, New Jersey, New York, Rhode Island, and Washington have enacted restrictions or outright prohibitions on 80% lower receivers. These laws often require serialization by licensed dealers or complete prohibition of possession.

Prohibited Persons and Compliance

Federal law prohibits firearm possession by individuals with felony convictions, domestic violence convictions (including misdemeanors), active restraining orders, mental health adjudications, illegal drug use, certain immigration statuses, or renounced citizenship. State laws may expand these categories or impose longer prohibition periods.

Maintaining proper documentation becomes crucial for legal compliance. Keep FFL transfer documents, document build configurations and dates, retain receipts for major components, and photograph configurations for insurance purposes. When modifying existing builds, research applicable laws for new configurations and ensure compliance with all federal and state requirements before making changes.

The legal framework surrounding AR-15 lower receivers continues evolving rapidly. Laws change frequently at federal, state, and local levels, making ongoing education essential. When facing complex legal questions or novel configurations, consult with qualified attorneys specializing in firearms law or contact knowledgeable FFL dealers in your area rather than relying solely on general information.

Types of AR Lowers

The difference between a stripped and complete lower is pretty obvious.

Have we mentioned AR versatility? When it comes to the choice of internal lower parts, triggers, grips, buffer tubes, and stocks/braces, there is a kaleidoscope of options available for the AR builder.

Complete Lowers

For ease of construction, complete lowers will be good to go right out of the box, just add a complete upper, bolt carrier group, and magazine, then function check and make sure it is lubed, and you are good to go.

This is especially appealing for first-time builders. Should you decide to, say, swap out a mil-spec hammer, hammer spring, disconnector, trigger, and bolt catch pin for an aftermarket drop-in trigger assembly as an upgrade, that is something that can typically be carried out later in under an hour with the help of a YouTube video.

Don’t end up liking it as much as you thought you would? Swap it back.

Stripped Receivers

For those looking to craft a gun from the bare receiver up, a stripped lower receiver is the way to go, allowing individual selection of LPKs and triggers, tubes, stabilizers, or the inclusion of an ambidextrous bolt release or custom roll marks like the above Frankengun lower from PSA.

This is appealing not only to AR snobs who will debate the finer points of a Timney Calvin Elite trigger compared to the Triggertech Adaptable trigger but also to those looking to build on a budget as oftentimes generic LPKs with standard no-name “military” grips and triggers can be had at value prices, sweat equity required.

Advanced Features Comparison

Beyond basic construction and materials, modern AR-15 lower receivers incorporate advanced features that can significantly enhance performance, ease of use, and customization potential. Understanding these features helps you select a lower that matches your specific needs and shooting style.

Ambidextrous Controls Overview

Ambidextrous features have evolved from simple safety selectors to comprehensive control systems that allow full manipulation from either side of the rifle.

Levels of Ambidextrous Functionality:

| Feature Level | Basic Ambi | Enhanced Ambi | Full Ambi | Examples |

|---|---|---|---|---|

Safety Selector | ✓ | ✓ | ✓ | All ambi lowers |

Magazine Release | — | ✓ | ✓ | Radian Battle Arms |

Bolt Catch | — | — | ✓ | Radian ADAC LMT MARS |

Bolt Release | — | ✓ | ✓ | Seekins Radian |

Price Range | $150-250 | $250-400 | $400-600 | Varies by manufacturer |

Practical Benefits:

- Left-Handed Shooters: Full access to all controls without awkward hand positioning

- Tactical Applications: Ability to operate rifle from either shoulder in confined spaces

- Injury Adaptation: Continued operation if dominant hand becomes compromised

- Training Consistency: Uniform manipulation regardless of shooting position

Enhanced Assembly Features

Modern lower receivers incorporate design improvements that simplify assembly and reduce the likelihood of damage during build process.

Traditional vs. Enhanced Assembly:

| Component | Traditional Method | Enhanced Method | Advantages |

|---|---|---|---|

Bolt Catch Pin | Roll pin installation | Threaded pin (Aero M4E1) | No marring easier installation |

Takedown Detent | Spring-loaded detent | Threaded set screw (Aero) | Prevents lost springs adjustable |

Trigger Guard | Separate installation | Integrated (most billet) | Stronger no installation required |

Pin Retention | Standard holes | Captured pins (some models) | Prevents pin loss during maintenance |

Builder-Friendly Features:

- Threaded Bolt Catch Pins: Found on Aero M4E1, eliminates difficult roll pin installation

- Set Screw Detents: Replaces traditional spring-loaded detents with threaded screws

- Enlarged Pin Holes: Some manufacturers slightly oversize holes for easier assembly

- Assembly Guides: Molded-in reference points for proper parts orientation

Precision Enhancement Features

Premium lower receivers often include features designed to improve accuracy and consistency.

Tension and Fitment Systems:

- Upper Tension Screws: Aero Precision, Noveske models allow fine-tuning of upper/lower fit

- Precision Tolerances: Billet lowers typically hold tighter dimensional accuracy

- Stress Relief: Advanced heat treating and machining reduces internal stress

- Bedding Systems: Some premium lowers include bedding points for enhanced accuracy

Trigger Pocket Enhancements:

- Enhanced Trigger Pocket: Wider dimensions to accept premium drop-in triggers

- Smooth Finishing: CNC-finished surfaces reduce friction and improve trigger feel

- Pin Hole Precision: Tighter tolerances on trigger and hammer pin holes

Ergonomic and Tactical Features

Advanced lowers incorporate features that enhance handling and operational efficiency.

Magwell Enhancements:

- Flared Magwells: Noveske, Battle Arms models speed magazine changes

- Beveled Edges: Reduce snag points and improve magazine insertion

- Reinforced Construction: Thicker walls in high-stress areas

- Texture Patterns: Some models include grip-enhancing textures

Trigger Guard Variations:

- Enlarged Guards: Accommodate gloved hands or trigger accessories

- Integrated Guards: Billet construction eliminates weak points

- Winter Guards: Oversized openings for extreme cold weather operation

- Tactical Guards: Enhanced protection against accidental trigger engagement

Weight Optimization Features

Advanced manufacturing techniques allow for significant weight reduction without compromising strength.

Weight Reduction Methods:

- Skeletonized Design: F-1 Firearms removes material in non-critical areas

- Strategic Lightening: Selective material removal based on stress analysis

- Optimized Geometry: Billet construction allows for strength-optimized shapes

- Advanced Alloys: Some manufacturers use specialized aluminum alloys

Weight Comparison by Feature Set:

| Lower Type | Typical Weight | Weight Savings | Strength Impact |

|---|---|---|---|

Standard Forged | 9.5-10.5 oz | Baseline | Excellent |

Enhanced Forged | 9.0-10.0 oz | 0.5 oz | Excellent |

Standard Billet | 8.5-9.5 oz | 1.0 oz | Excellent |

Lightweight Billet | 6.8-8.0 oz | 2.5 oz | Very Good |

Skeletonized | 5.5-7.0 oz | 4.0 oz | Good |

Material and Finish Upgrades

Premium lowers often feature advanced materials and finishing processes that enhance durability and appearance.

Advanced Anodizing Options:

- Type III Hardcoat: Standard on premium models, superior wear resistance

- Color Options: ODG, FDE, and custom colors available on many models

- Texture Variants: Matte, glossy, and textured finishes for different applications

- Multi-Layer Systems: Some manufacturers use multiple coating layers

Special Material Treatments:

- Stress Relief: Advanced heat treating reduces dimensional changes over time

- Surface Hardening: Specialized treatments increase surface hardness

- Corrosion Resistance: Enhanced treatments for marine or harsh environments

- Tool Steel Inserts: Some premium models use hardened steel in high-wear areas

Compatibility Considerations for Advanced Features

While advanced features offer significant benefits, they may impact compatibility with standard components.

Potential Compatibility Issues:

- Proprietary Magazines: Some enhanced magwells work best with specific magazine types

- Trigger Compatibility: Enhanced trigger pockets may not work with all aftermarket triggers

- Stock Systems: Specialty buffer tubes may limit stock selection

- Optics Mounting: Some enhanced features may interfere with certain optic mounts

Selection Guidelines:

- Match Features to Use Case: Competition builds benefit from different features than tactical builds

- Consider Future Upgrades: Ensure advanced features align with planned modifications

- Evaluate Cost/Benefit: Determine if advanced features justify additional cost

- Research Compatibility: Verify that enhanced features work with intended components

Manufacturing Quality Indicators

Advanced features often serve as indicators of overall manufacturing quality and attention to detail.

Quality Markers:

- Consistent Dimensions: Advanced features require precise manufacturing

- Smooth Operation: Enhanced controls should operate smoothly without binding

- Finish Quality: Premium features typically indicate superior finishing processes

- Documentation: Quality manufacturers provide detailed specifications and compatibility information

Understanding these advanced features helps you select a lower receiver that not only meets your current needs but also provides room for future upgrades and modifications. While basic forged lowers excel for standard builds, advanced features become increasingly valuable for specialized applications, competition use, or builds where every detail matters.

Market Trends & Product Updates

The AR-15 lower receiver market continues evolving rapidly, driven by technological innovations, regulatory changes, and shifting consumer demands. Understanding current trends and recent product releases helps builders make informed decisions about their next purchase.

Supply Chain Stabilization and Pricing Trends

After the volatility of 2020-2022, the AR-15 lower receiver market has largely stabilized in 2024-2025. Manufacturing capacity has expanded significantly, with established companies like Aero Precision, Palmetto State Armory, and Anderson Manufacturing increasing production to meet sustained demand. This expansion has created more predictable availability and pricing across most categories.

Budget lower receivers now consistently price between $45-75, representing excellent value for builders seeking mil-spec functionality. Mid-tier options from companies like Aero Precision and DoubleStar USA have settled into the $85-150 range, while premium billet options continue commanding $200-500+ depending on features and manufacturer reputation.

The most significant pricing pressure has occurred in the premium segment, where increased competition has forced manufacturers to offer more features at lower price points. Companies like Seekins Precision and Battle Arms Development have responded by enhancing their value propositions rather than simply raising prices.

Regulatory Impact and Adaptation

The ATF’s 2022 ruling on 80% receivers has fundamentally reshaped this market segment. Commercial 80% lower sales now require background checks and serialization, effectively eliminating the previous appeal of these products for many consumers. However, this change has driven increased demand for traditional stripped lower receivers as builders seek affordable customization options.

State-level restrictions continue expanding, with several jurisdictions implementing new “assault weapon” definitions or enhanced registration requirements. Manufacturers have responded by developing compliant variants and offering configuration guidance for restrictive states. This trend has created specialized product lines optimized for compliance in states like California, New York, and Connecticut.

Technological Innovations and Enhanced Features

The most significant trend in lower receiver development involves enhanced assembly features designed to simplify the build process. Aero Precision’s threaded bolt catch pins have proven so popular that other manufacturers are incorporating similar innovations. Seekins Precision has expanded their screw-in pin concept, while several companies now offer captured pin systems that prevent component loss during maintenance.

Ambidextrous controls have evolved from expensive novelties to mainstream features. Companies like Radian Weapons and Battle Arms Development continue refining their fully ambidextrous designs, while more manufacturers offer basic ambidextrous safety selectors as standard equipment. This trend reflects both increased left-handed shooter participation and tactical applications requiring ambidextrous capability.

Weight optimization has become increasingly sophisticated, with manufacturers using advanced stress analysis to identify optimal material removal locations. F-1 Firearms continues leading the ultra-lightweight segment, but companies like Seekins Precision and V Seven have introduced their own weight-optimized designs that maintain full strength characteristics.

2024-2025 Product Highlights

Aero Precision has expanded their EPC-9 lineup with new caliber options and enhanced magazine compatibility. Their M4E1 platform now includes additional color options and improved tension screw systems based on user feedback. The company has also introduced builder-friendly packaging with enhanced instruction materials.

Daniel Defense has entered the standalone lower receiver market with their new DDM4 stripped lowers, featuring premium tolerances and their signature finish quality. These lowers include integrated trigger guards and enhanced magwell geometry optimized for their upper receiver systems.

Geissele Automatics has refined their Super Duty lower receiver design with improved trigger pocket specifications and enhanced compatibility with their trigger systems. The company has also introduced new color options and improved availability through expanded dealer networks.

Palmetto State Armory continues expanding their complete lower offerings with new furniture combinations and enhanced trigger options. Their partnership with various accessories manufacturers has created value-packed complete lowers that compete directly with custom builds.

Sons of Liberty Gun Works has gained significant market attention with their enhanced forged lowers that bridge the gap between basic mil-spec and premium billet options. Their focus on practical enhancements rather than aesthetic features has resonated with serious builders.

Emerging Market Segments

The pistol caliber carbine (PCC) segment continues growing rapidly, driven by competition shooting popularity and home defense applications. Manufacturers have responded with dedicated 9mm lower receivers optimized for specific magazine types. Aero Precision’s EPC-9 platform has spawned competitors from companies like Foxtrot Mike and New Frontier Armory, each offering unique approaches to PCC optimization.

Competition-focused lowers represent another growing segment, with features specifically designed for 3-Gun, PRS, and precision rifle applications. These products typically include enhanced magwells, optimized trigger pockets, and weight distribution designed for specific competitive disciplines.

Future Development Directions

Manufacturing technology continues advancing, with several companies investing in advanced CNC capabilities and automated production systems. This investment should drive continued quality improvements while maintaining competitive pricing. Some manufacturers are exploring alternative materials and advanced heat treatment processes that could offer enhanced performance characteristics.

The integration of smart technology represents a potential future direction, though current legal frameworks limit implementation. Manufacturers continue researching applications that could enhance safety or performance while maintaining compliance with existing regulations.

Quality control standards across the industry have improved significantly, with even budget manufacturers implementing enhanced inspection protocols. This trend benefits consumers through reduced variance and improved reliability across all price segments.

Looking ahead, the lower receiver market appears positioned for continued innovation focused on practical enhancements rather than purely aesthetic improvements. Manufacturers increasingly recognize that builders value functional improvements that enhance assembly ease, long-term reliability, and shooting performance over purely cosmetic features.

The combination of stable supply chains, technological innovation, and competitive pressure should continue benefiting consumers through improved products at competitive prices across all market segments.

What should you expect to pay?

Due to the variety of features available on lowers can vary so much, so does pricing. For under $100, it’s possible to get a quality forged or billet lower that comes totally bare.

- Over $100, you’ll be getting some parts that come with the lower, such as a basic trigger, magazine release, etc. But it’s unlikely any of the parts will be especially fancy or high-end. Expect lots of mil-spec goodness and little worry about quality control.

- At the $200 mark, it’s more likely that you’ll get either a buttstock or an upgraded trigger. At this price point, some fancier finishes are also available.

- Above $300, you can expect a lower that comes fully ready to go, and many of them will come with upgraded parts that are intended for accurate rifles and competition guns.

As you can see, it’s more than possible to get into AR building with a stripped lower at a relatively low price.

This is one of the things that I like so much about buying lowers: it gives people a chance to get into an AR for an extremely reasonable price, and then you can learn something about building a complete rifle along the way. I’d recommend going for a stripped lower if you want to save money and are up for a little bit of a challenge.

Additional Resources

- GunCraft101. (2019) Making an AR15 from beer cans 2011

- Clinton Aluminum. (2017) 6061 VS. 7075

- 80% Lowers. (2020) AR-15 Coatings Explained

Updated

Sign up for our newsletter

Get discounts from top brands and our latest reviews!